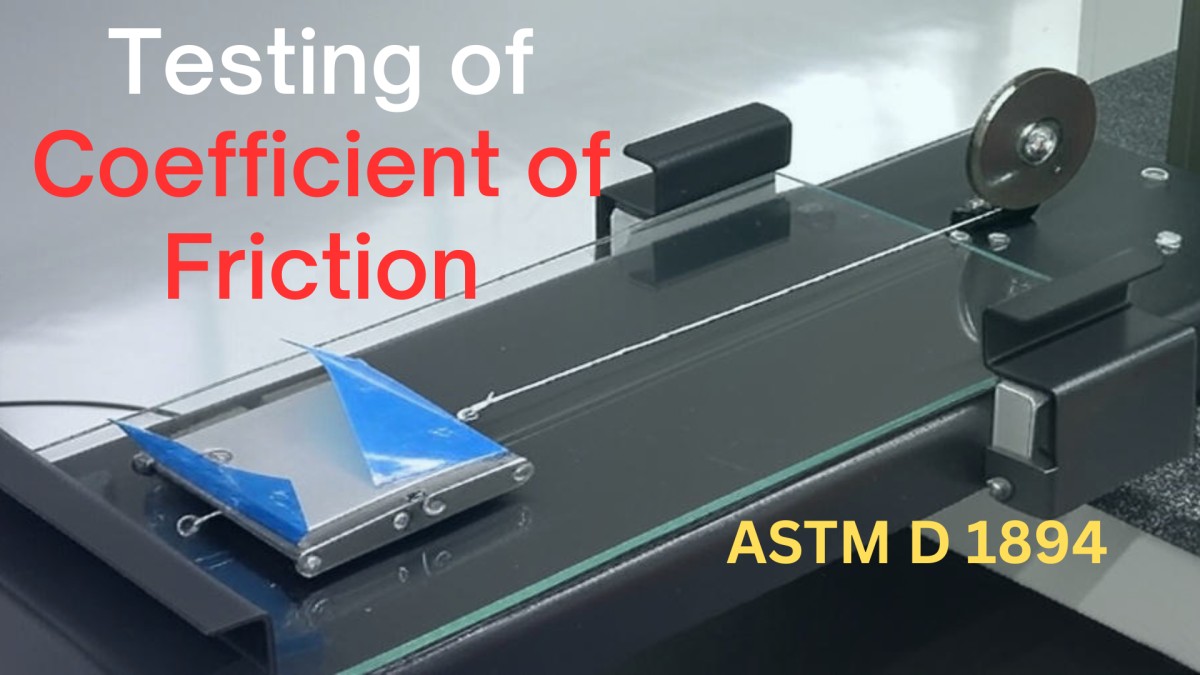

Understanding Tensile Test Standards for Plastics – ASTM D638 & ISO 527

In this Blog we using ASTM D 638 /ISO 527 for Tensile Strength, Elongation at break of plastic material

(a) Tensile Strength – It is the ability of a material to withstand forces that to pull it apart and to determine to what extent the material stretches before breaking. Unit: Kgf/cm2

(b) Tensile Modulus: The ratio of tensile stress to corresponding strain at the maximum load within the proportional limit is known as tensile modulus. Unit: Kg/ cm2

(c) Percentage of Elongation at Yield: It is defined as the percentage elongation produced in the gauge length of the test piece at the yield tensile stress. Unit: %

(d) Percentage of Elongation at Break: It is defined as the elongation at break or at maximum load, produced in the gauge length of the test piece. Unit: %

Test Method: ASTM-D 638, ISO-527

Specimen Dimension: Dumb-bell shaped

The most common specimen for ASTM D638 is a Type I tensile bar. The most common specimen for ISO 527 is the ISO 3167 Type 1A multipurpose specimen. ASTM D882 uses strips cut from thin sheet or film

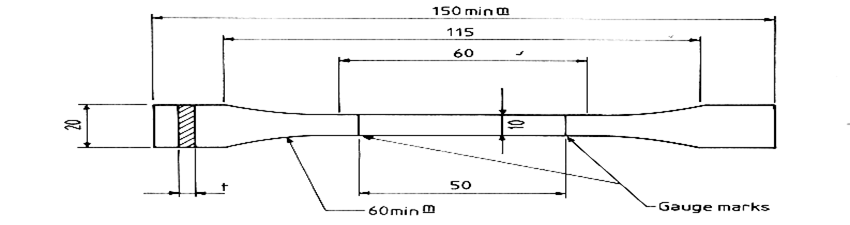

Tensile test piece ISO / DIS 527 Type 1(Broad-waisted Dumb-bell)

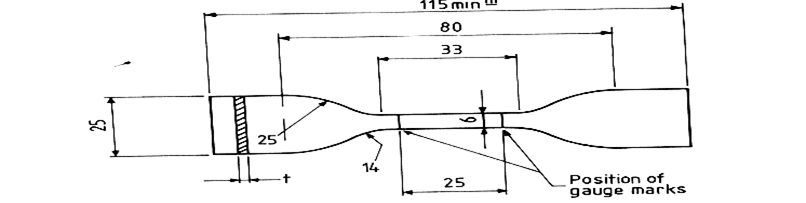

Tensile test piece ISO / DIS 527 Type 2 (Narrow-waisted Dumb-bell)

Conditioning: Prior to the testing, samples are conditioned at 23 ± 2°C and 50 ± 5% or 27 ± 2°C and 65 ± 5% relative humidity for 48 hours in accordance with procedure as per ASTM D 638.

Test Procedure: Specimens are placed in the grips of the tensile tester or Universal Testing Machine (UTM) at a specified grip separation and pulled until failure. For ASTM D638 the test speed is determined by the material specification. For ISO 527 the test speed is typically 5 or 50mm/min for measuring strength and elongation and 1mm/min for measuring modulus. An extensometer is used to determine elongation and tensile modulus

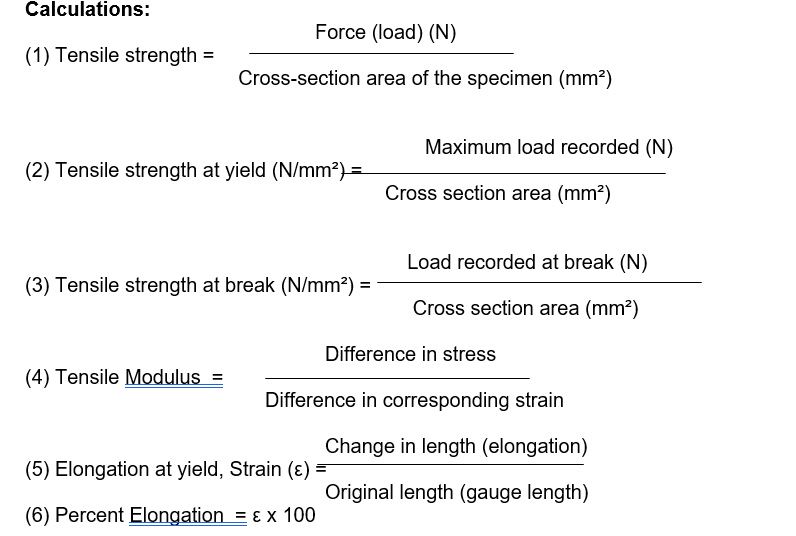

Calculations:

Post Comment