UPVC Pipe Test as per IS 4985

Water supply systems frequently use unplasticized polyvinyl chloride (UPVC) pipes because of their affordability, longevity, and resistance to corrosion. Engineered for outstanding performance, PVC pipes are created to withstand and perform effectively in numerous applications.

Designed for longevity, our pipes provide exceptional strength and adaptability, meeting the most stringent industry benchmarks. PVC pipes and fittings offers a great option for the transportation of both hot and cold water, enhancing your daily life with comfort and convenience.

PVC Pipe are engineered to provide reliability, whether it’s for water supply, sewage, or gas.

.The specifications for UPVC pipes used for irrigation and potable water delivery are outlined in the Indian Standard IS 4985

Fundamental of UPVC Pipes as per IS 4985:

- Material: Made from unplasticized PVC (no added phthalates), ensuring safe drinking water conveyance.

- Pressure Rating: Available in different pressure classes:

- Class 1: 2.5 kg/cm²

- Class 2: 4 kg/cm²

- Class 3: 6 kg/cm²

- Class 4: 8 kg/cm²

- Class 5: 10 kg/cm²

- Class 6: 12 kg/cm²

IS 4985 Consists of following major Tests:

- Dimensions

- Hydrostatic Characteristics

- Visual Appearance

- Opacity

- Effect on Water

- Reversion Test

- Vicat Softening Temperature.

- Density

- Sulphated Ash Content Test

- Marking

Testing Procedure:

Dimensions: Dimensions consists of Mean Outside Diameter, Dia at any point, Wall Thickness etc. Dimensions are checked by using Pie-tape, Vernier caliper and micrometer

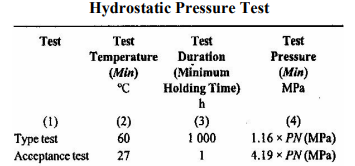

Hydrostatic Characteristics: Test is done by Internal Hydostatic pressure testing machine.

Visual Appearance: The colour of the pipes shall be light grey.

Opacity: Opacity is done by using opacity tester machine

Effect on Water: This test is done by using ICP-MS And ICP-OS also.

Reversion Test : When tested by the immersion method prescribed in IS 12235 (Part 5), a length of pipe 200 ± 20 mm long shall not alter in length by more than 5 percent.

Vicat Softening Temperature.: When tested by the method prescribed in IS 6307, the Vicat softening temperature of the specimen shall not be less than 80°C

Density: When determined in accordance with IS 13360 (Part 3/Sec 1), the density of the pipe shall be between 1.40 and 1.46

Sulphated Ash Content Test: When tested as per Annex B of IS 4985, the sulphated ash content

in the pipe shall not exceed 11 percent.

Post Comment