Flexural Strength Characterization: A Study Based on ASTM D-790 and ISO 178 Standards

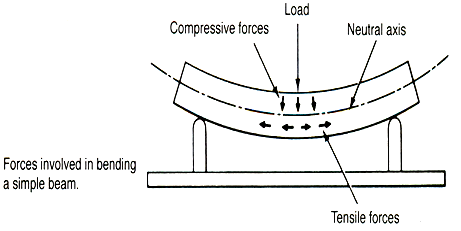

Flexural strength is the ability of the material to withstand bending forces applied perpendicular to its longitudinal axis. The stresses induced due to the flexural load are a combination of compressive and tensile stresses. Unit-Kg/cm2

Flexural Modulus: Within the elastic limit, the ratio of the applied stress on a test specimen in flexure to the corresponding strain of the specimen is known as flexural modulus. Unit-Kg/cm2

Test Method: ASTM-D-790, ISO 178, BIS-7203-1982, BS-2782.

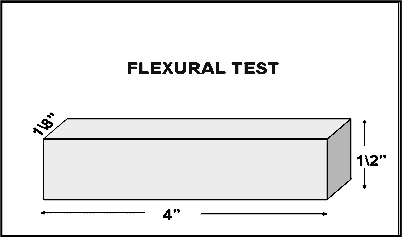

Specimen Dimensions Specimen are rectangular bar of 127mm x 12.7mmx 3 mm size

Test Procedure:

There are two test methods for flexural test.

- Three point bending method

- Four point bending method

Three Point Bending Method (Test Method-I): It is a three-point loading system utilizing center loading on a simple supported beam. A bar of rectangular cross section rest on two supports & is loaded by means of a loading nose midway between the supports the maximum axial fiber stresses occur on a line under loading nose.

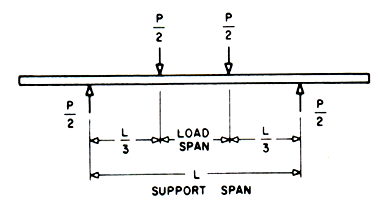

Four Point Bending Method (Test Method-II): It is four -point loading system utilizing two load points equally spaced from their adjacent supports point, with a distance between load points of one-third of the support span. In this method, the test bar rests on two supports & is loaded at two point (by means of two loading noses), each on equal distance from the adjacent support point. This method is very useful in testing materials that do not fail at the point of maximum stress under a three-point loading system the maximum axial fiber stress occurs over the area between the loading noses.

Calculation:

- Calculate the rate of cross-head motion as follows and set the machine for the calculated rate, or as near as possible to it,

R = Zl2 / 6d

Where,

R = rate of cross-head motion (mm/min)

l = support span (mm)

d = depth of beam (mm)

Z = rate of straining of entire fiber (mm/min)

2) Terminate the test when the maximum strain in the outer fiber has reached 0.05 mm/min. The deflection at which distortion occurs are calculated by ‘r’ equal to 0.05 mm/min as follows:

D= rl2 / 6d

Where,

D = midspan deflection (mm)

r = strain (mm/mm)

l = support span

d = depth of beam (mm)

- (3) Max.fiber stress- test method

S = 3PL / 2 bd2

Where, S = stress in the outer fiber at midspan (Mpa)

P = load at given point on the load deflection curve (v)

L= support beam (mm)

b= width of beam tested (mm) d = depth of beam tested in (mm

Factors Influencing:

- Specimen Preparation: Injection moulded specimen usually shows a higher flexural value than a compression moulded specimen.

- Temperature: Flexural Strength and Modulus value are inversely proportional with temperature.

- Test Conditions: The strain rate, which depends upon testing speed; specimen thickness and distance between supports (span), can affect the results. At a given span, Flexural Strength increases as the specimen thickness is increased. Modulus of a material generally increases with increasing strain rate.

Post Comment