Testing of CPVC Pipes for Potable Hot and Cold Water Distribution Systems as per IS 15778

Chlorinated polyvinyl chloride is used to make CPVC plumbing systems, which are produced in accordance with IS 15778. Polyvinyl chloride (PVC) resin is chlorinated to create chlorinated polyvinyl chloride (CPVC), a thermoplastic that is far more flexible and heat-resistant than regular PVC.

A demanding new benchmark for hot and cold water plumbing system performance is set by cPVC.

CPVC offers outstanding value while resolving many of the issues with traditional CPVC thanks to its sophisticated, novel chemical formula.

CPVC is impervious to corrosive substances, coastal salt air, and low pH water.

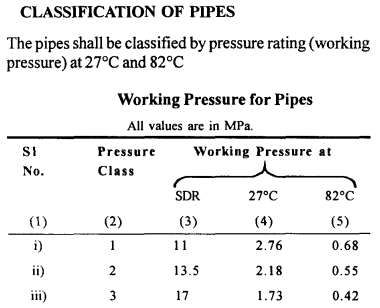

As per IS 15778 CPVC PIPES ARE CLASSIFIED AS FOLLOWS :

Major test of cPVC pipe as per IS 15778

(1) Visual Appearance : The colour of the pipes shall be off white. The internal and external surfaces of the pipe shall be smooth, clean and free from grooving and other defects

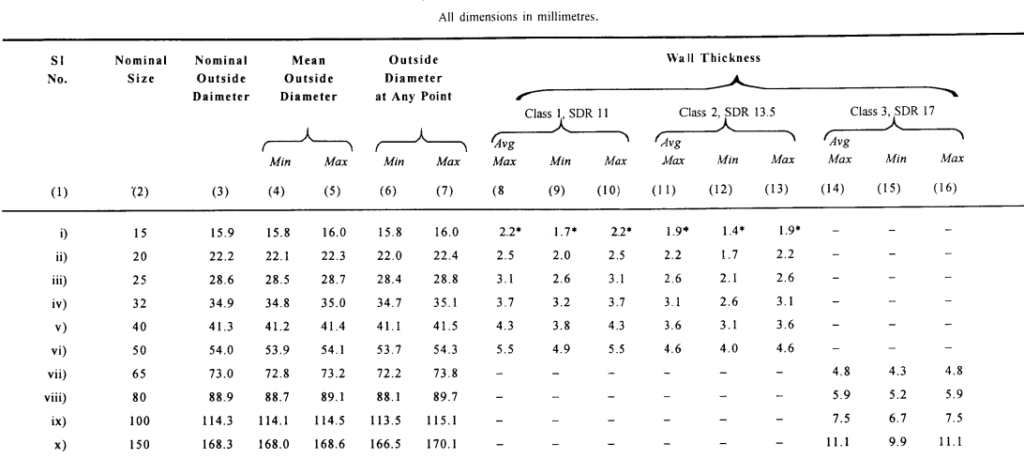

(2) Dimensions, mm : It is measured by using Vernier Caliper , micrometer and Pie tape

(3) Opacity, % – 0.2 Maximum

(4) Reversion, % – 5 Maximum

(5) Vicat Softening Temperature,°C –110 Minimum

(6) Density at 27°C, kg/m³ –1450-1650

(7) Resistance to external blows at 0°C (True impact rate), % –10 Maximum

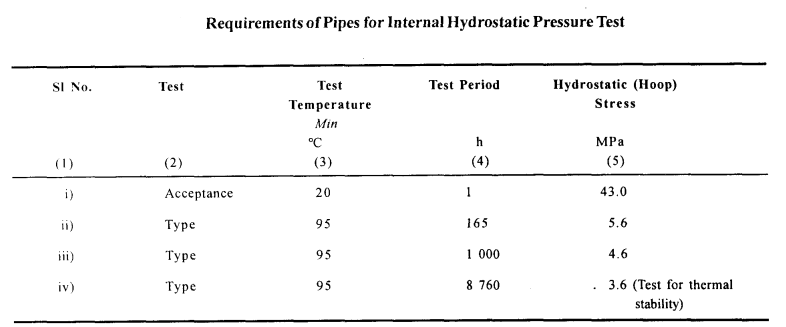

(8) Hydraulic Characteristics :

(a) Acceptance test (at 27°C for 1 hours, Hoop stress 43 MPa)-Shall not fail during the prescribed test duration

(b) Type test (at 95°C for 165 hours, Hoop stress 5.6 MPa)-Shall not fail during the prescribed test duration

(9) Flattening test : Sample shall show no sign of cracking, splitting and breaking

(10)Tensile strength at yield, MPa : 50 Minimum

(10) Effect on water : This Test is done by using ICP-MS & ICP-OES Instruments.

(i) Lead content, mg/l 1st extraction – 1.0 maximum 3rd extraction – 0.05 Maximum

(ii) Cadmium content, mg/l

1st extraction 2nd extraction 3rd extraction – 0.01 Maximum

(iii) Mercury content, mg/l

1st extraction 2nd extraction 3rd extraction – 0.001 Maximum

(iv) Tin content, mg/l 3rd extraction – 0.02 Maximum

Dimensions of cPVC Pipes are given in below: As per IS 15778

Composition : The material from which the pipe is produced shall consist substantially of chlorinated polyvinyl chloride to which may be added only those additives that are needed to facilitate the manufacture of the pipe and the production of sound and durable pipe of good surface finish, mechanical strength and opacity under conditions of use. None of these additives shall be used separately or together in quantities sufilcient to constitute a toxic, organoleptic or microbial growth

hazard or materially to impair the fabrication or welding properties of the pipe, or to impair the chemical, physical or mechanical properties (in particular long-term mechanical strength and impact strength).

Resin chlorine content : shall have chlorine content not less than 66.5%

Compound chlorine content : shall have chlorine content not less than 60 %

Hydraulic Characteristics :

When subjected to internal hydrostatic pressure test in accordance with the procedure given in IS 12235

(Part 8/See 1), the pipe shall not fail during the prescribed test duration. The temperatures, duration and

hydrostatic (hoop) stress for the test shall conform to the requirements given in below Table

Pipe’s pressure rating: Its diameter and wall thickness also need to be factored.

S = P (D-t) / (2t) Or S = P (d+t) / (2t)

Where:

- S = Stress

- P = Pressure

- D = Average outside diameter

- d = Average inside diameter

- t = Minimum wall thickness

The value derived from this formula is the pressure rating you’ll see printed on the side of a pipe. It is based on the pipe’s performance at 23°C in potable water application.

Advantage of CPVC Pipe : Residential Plumbing: Due to their capacity to endure elevated temperatures and pressures, CPVC pipes are extensively utilized in residential structures for the distribution of potable water, hot water systems, and the removal of wastewater. A key reason for the adoption of CPVC in residential environments is that these pipes guarantee the absence of harmful or hazardous substances in the water, rendering it a safe option.

Commercial Plumbing: In commercial settings such as hotels, hospitals, schools, and offices, CPVC pipes provide a dependable and effective plumbing solution. These pipes are resistant to corrosion, resistant to bio-film, and capable of withstanding high temperatures, making them an optimal choice for commercial uses.

Post Comment