Skip to content

The mechanical testing of polymers is a significant aspect of the product development and production process. Mechanical, thermal, optical, rheological behaviour and environment testing allow the creators to better understand their product, and introduce greater quality control.

Polymer testing, both mechanical and physical, guarantees that the material meets industrial standards. This holds true for a variety of industries, including the consumer, automotive, aerospace, medical, and defense sectors. Understanding a material’s potential and limitations is crucial for manufacturers, suppliers, and product developers at every stage of the polymer industry supply chain, given the wide variety of product types and additives available.

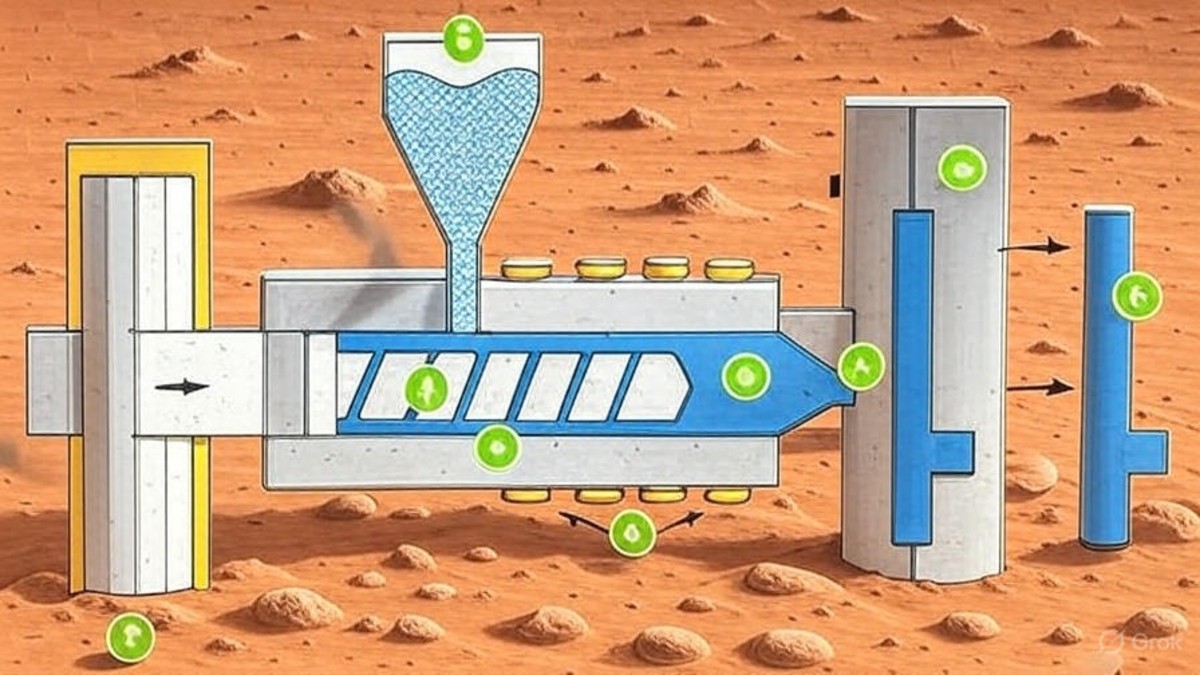

Injection Moulding Basics (Part 1): Everything You Need to Know

In the mass-production manufacturing technique known as injection molding, molten materials—most frequently thermoplastic polymers—are injected…

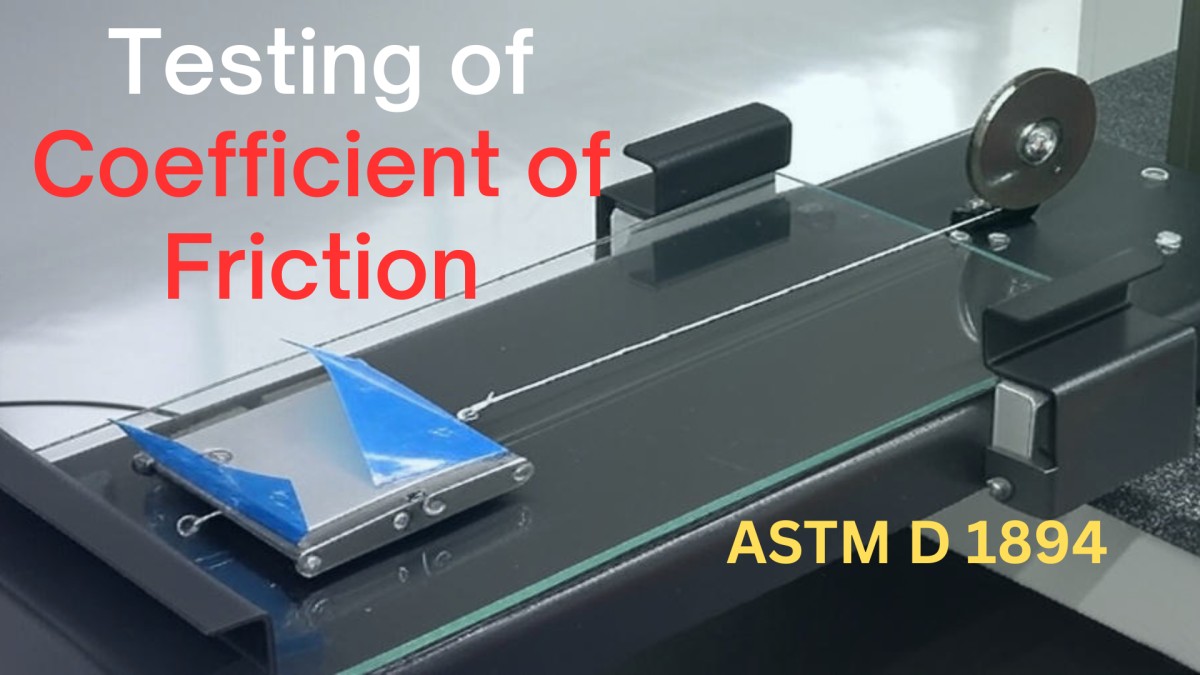

Testing and Evaluation of Coefficient of Friction (COF) Following ASTM D 1894

Coefficient of friction- It is the ratio of the frictional force to the force, usually…

How to Calculate Hardness: Rockwell & Durometer Methods Explained

Hardness is defined as the “resistance of a material to deformation” particularly permanent deformation, indentation…

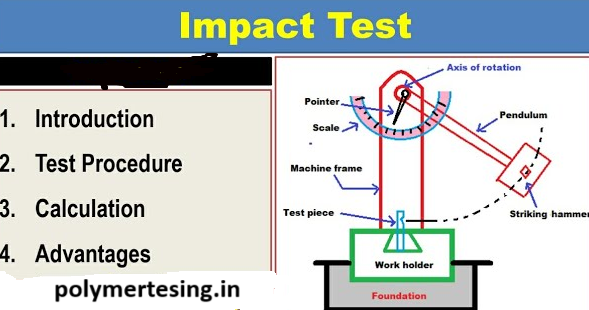

How to Measure Impact Strength? ASTM D256 Izod vs. Charpy Explained

Impact strength: Impact strength is defined as the ability of material to absorb applied energy.…

Flexural Strength Characterization: A Study Based on ASTM D-790 and ISO 178 Standards

Flexural strength is the ability of the material to withstand bending forces applied perpendicular to…

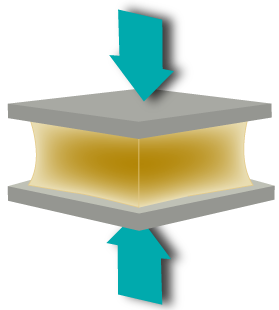

Compressive Strength Analysis of Polymeric Materials: A Study Based on ASTM D695 and ISO 75 Standards

In This Method we study about compressive strength using various standard ASTM D 695, ISO…

Understanding Tensile Test Standards for Plastics – ASTM D638 & ISO 527

In this Blog we using ASTM D 638 /ISO 527 for Tensile Strength, Elongation at…

Mechanical Testing: Tensile Testing Various Terms

The mechanical properties of plastics can be broadly classified as short-term, long-term and surface properties.…

Disclaimer

If you require any more information or have any questions about our site's disclaimer, please…