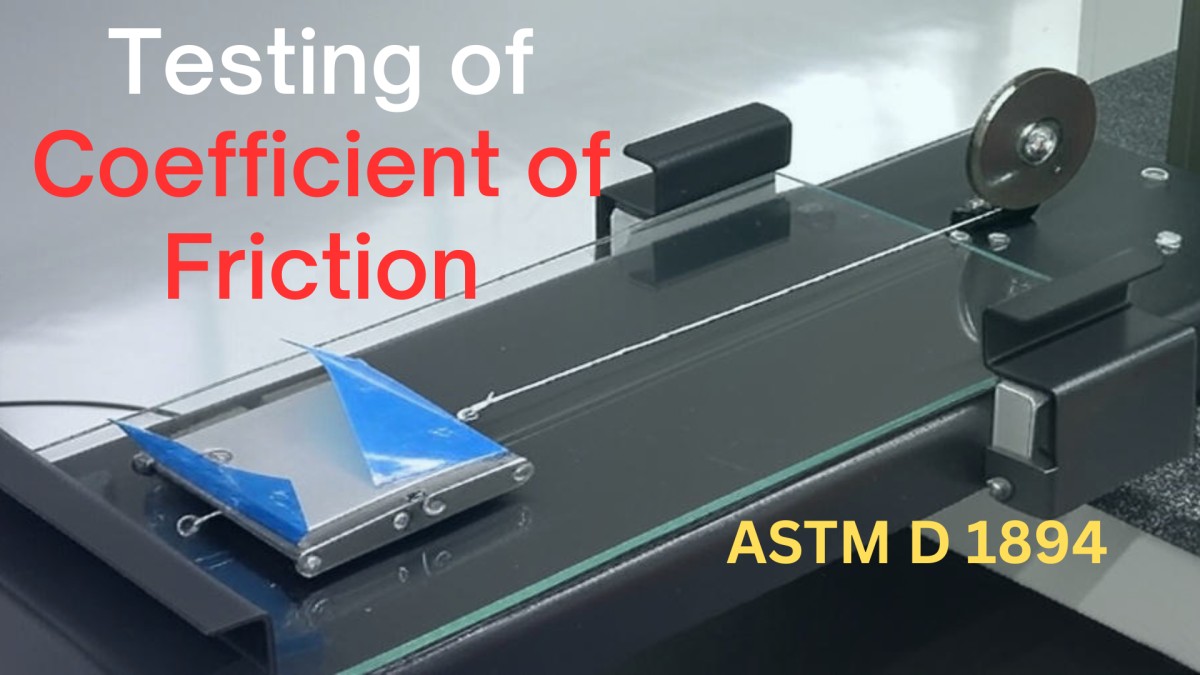

Compressive Strength Analysis of Polymeric Materials: A Study Based on ASTM D695 and ISO 75 Standards

In This Method we study about compressive strength using various standard ASTM D 695, ISO 75-1 AND 75-2. Here We study about different terms used during compression test calculation

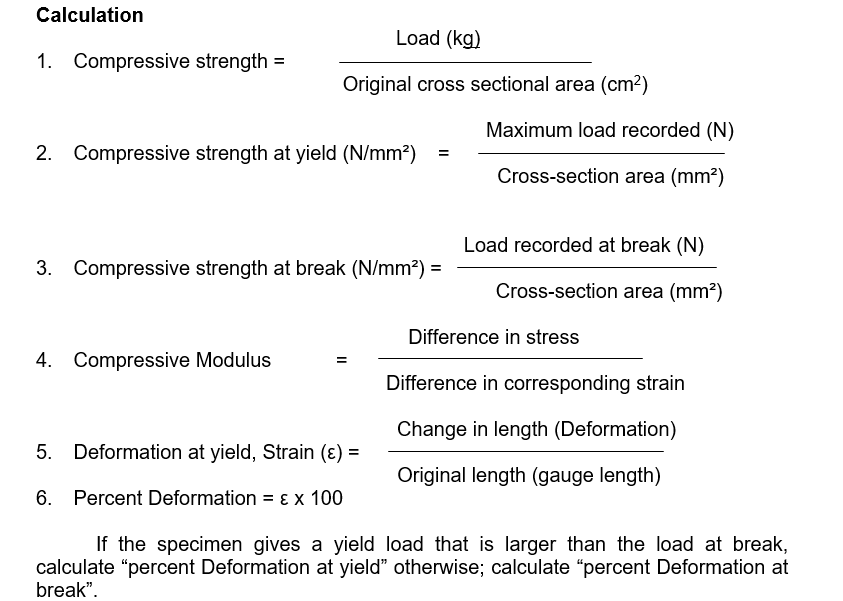

Compressive Strength: It is the ratio of the maximum load sustained by a test specimen in a compressive test to the original cross section area of the specimen. Unit: kg/cm2

Compressive Deformation: The decrease in length produced in the gauge length of the test specimen by a compressive load. It is expressed in unit of length.

Compressive Strain: The ratio of compressive deformation to the gauge length of the test specimen, i.e., the change in length per unit of original length along the longitudinal axis. It is expressed as dimension ratio.

Slenderness Ratio: The ratio of the length of a column of uniform cross section to its least radius of gyration known as slenderness ratio.

Modulus of Elasticity: The ratio of stress to corresponding strain below the proportional limit of a material. It is expressed as force per unit area, based on the average initial cross- sectional area.

Compressive Yield Point: The fist point of stress-strain diagram at which an increase in strain occurs without an increase in stress.

Test method: ASTM D 695, ISO 75-1 AND 75-2

Specimen Dimension:For cylindrical specimen: 12.7mm dia x 25.4mm long

For rectangular specimen: 12.5mm x 12.5mm x 25.4mm

Test procedure:

- Measure the width and thickness of the specimen to the nearest 0.01 mm at several points along its length.

- Calculate and record the minimum value of the cross-sectional area.

- Measure the length of specimen and record the value.

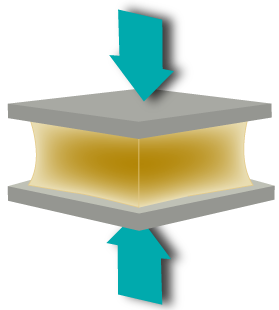

- Place the test specimen between the surfaces of the compression tool, taking care to align the center of its long axis with the centreline of the plunger and to ensure that the ends of the specimen are parallel with the surfaces to the compression tool.

- Place thin specimens in the jig so that they are flush with the base and centered.

- If only compressive strength, then set the speed control at 1.0 mm / min and start the machine.

- If strain- stress data are desired then,

- Attach compressor

- Record load and corresponding compressive strength at appropriate intervals of strain.

- After the yield point reach, it is desirable to increase the speed from 5 to 6 mm/min. and allow machine to run at this speed until the specimen breaks.

Conditioning: Test specimens are conditionedat 23 ± 2°C and 50 ± 5% or 27 ± 2°C and 65 ± 5% relative humidity for 48 hours.

Factors Influencing:

- Temperature and Humidity: Compressive strength decreases as temperature increase. Moisture acts as plasticizer, there by decreasing the compressive strength and increase the deformation.

- Method of specimen Preparation – Molecular Orientation has a significant effect on Compressive Strength values. A load-applied parallel to the direction of molecular Orientation may yield higher value than the load applied perpendicular to the orientation. The opposite is true for elongation.

- Rate of Straining– As the strain rate increases, Compressive Strength and modulus increases, and deformation is inversely proportional to the strain rate.

- Molecular Weight and Molecular Weight Distribution: Increase in molecular weight increases the compressive strength. Smaller molecules in polymer acts as plasticizer. Hence increase in molecular weight distribution, decreases deformation and increases compressive strength.

- Crystallinity Increase in crystallinity increases in compressive strength

Post Comment