CPVC Pipes for Automatic Sprinkler Fire Extinguishing Systems as per IS 16088

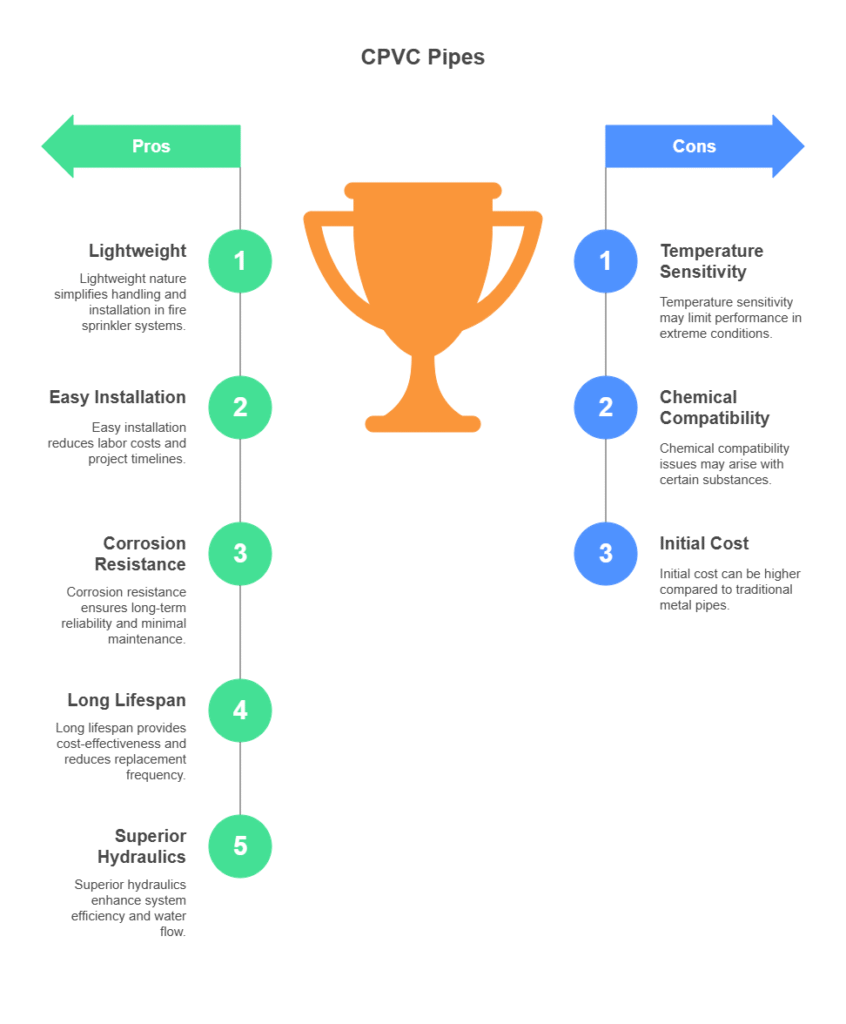

Lightweight and easy to transport, CPVC pipes are simple to install and resistant to corrosion, boasting an impressive lifespan. They possess superior hydraulic properties with a Hazen Williams C factor of 150, compared to the 120 found in steel pipes. As This makes CPVC material a preferred option for designers when choosing fire sprinkler systems instead of metal. In the event that Due to its high Limiting Oxygen Index (LOI) of 60, it is self-extinguishing and needs very high levels of oxygen to sustain combustion.

proportion of oxygen present in the atmosphere to sustain combustion. CPVC pipes have taken the place of steel pipes in the setup of automatic sprinkler systems for fire suppression in Many nations around the globe have been providing seamless service effectively since 1986.

For details: click below link our Podcast channel

CLASSIFICATION OF PIPES :

The working pressure of pipes is 2.17 Mpa (315 PSI) at 23°C and 1.21 Mpa (175 PSI) at 65°C

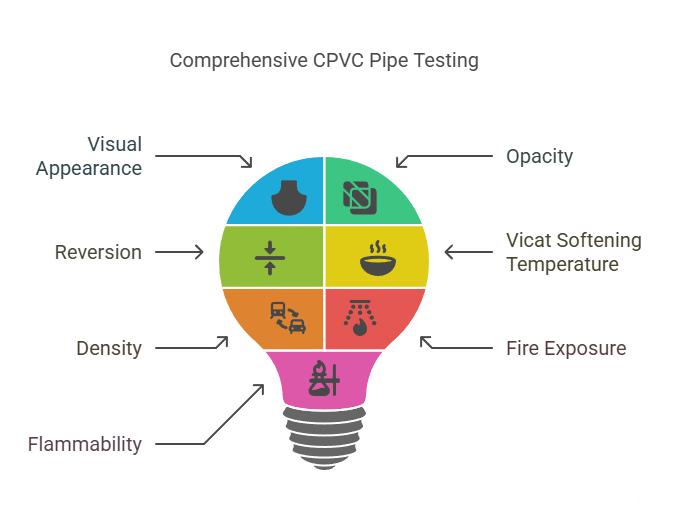

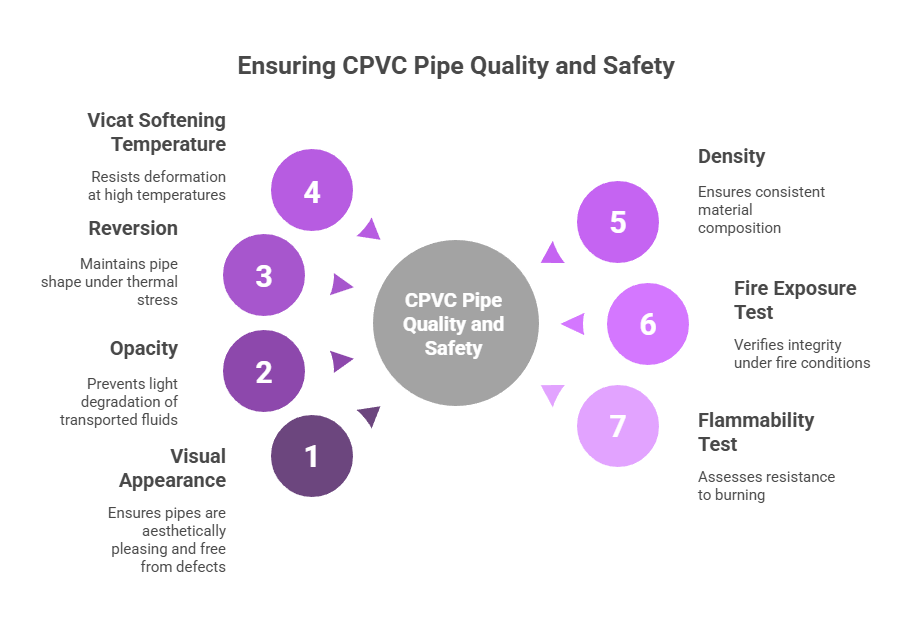

Major Testing parameter of CPVC Pipe as per IS 16088

(1) Dimensions of Pipe : Dimensions are measure with the help of Pie Tape, Vernier caliper and Thickness Gauge

a) Mean outside dia

b) Outside diameter at any point

c) Wall thickness

(2) PHYSICAL & CHEMICAL TEST:

(a) Visual Appearance: The colour of the pipes shall be orange. The internal & external surfaces of the pipe shall be smooth, clean & free from the grooving and other defects

(b) Opacity ,% – Measured by opacity tester. It shuld be 0.2% Maximum

(c) Reversion, %- It should be 5% maximum

(d) Vicat softening Temperature °C- It should be 110 Minimum

(e) Density at 27°C, kg/m³– It should be 1450-1540 kg/m³

(f) Fire Exposure Test : Fire testing of CPVC pipes and fittings must be conducted for a duration of 10 minutes. according to the testing guidelines outlined in Annex B of IS 16088. During the assemblies of pipe and fittings subjected to fire testing must not rupture, isolate or release and will keep the sprinkler in the designated operational stance. In the aftermath of the blaze exposure, the assemblies of pipes and fittings shall endure an internal hydrostatic pressure that is equivalent to the maximum pressure rating maintained for 5 minutes without failure or leaks.

(g) Flammability Test : It should pass V-0 rating.

(3) MECHANICAL PROPERTIES :

(a) Hydrostatic Characteristics:

Short Term Test: Pipe sample shall withstand for 1 min without rupture, separation or leakage an internal hydrostatic pressure of five times the rated pressure at room temperature.

Long Term Test : Pipe shall withstand for 1 000 h without rupture, separation or leakage an internal hydrostatic pressure of 2.55 MPa at 65°C.

(b) Resistance to External Blow at 0°C– Pipe shall have a true impact rate of not more than 10 percent.

(c) Flattening Test: Pipe shall show no signs of cracking, splitting and breaking.

(d) Tensile Strength at yield : The tensile strength at yield shall not be less than 53 MPa at 27± 2°C.

(e) Kinking Resistance Test : Sample of the pipe shall not kink at or above the minimum bending radius values specified in Table 3 of IS 16088

COMPOSITION : The substance utilized in the creation of the pipe must primarily composed of chlorinated polyvinyl chloride. Additives necessary for smooth functioning might be incorporated.

the creation of the tube and the generation of noise and sturdy pipe with a quality surface finish, mechanical power and density in practical application scenarios. None of these additives can be utilized individually or in combination in amounts adequate to form a toxic, sensory-relate or the risk of microbial growth or significantly affect the manufacturing, or to weaken the chemical, physical, or

mechanical characteristics (especially over extended periods) mechanical resilience and toughness against impacts as specified in this IS 16088

Compound Chlorine Content : The compounds used in pipes made of chlorinated polyvinyl chloride

including substances like lubricants, modifiers, fillers, etc., from which the pipes will be taken

produced, must contain chlorine levels of no less than 55%

Conclusion :

In fire sprinkler systems, CPVC pipes present numerous benefits that surpass those of conventional metal pipes. Designers and installers favor them due to their lightweight design, simple installation, resistance to corrosion, longevity, excellent hydraulic qualities, and fire-retardant features. Since 1986, CPVC pipes have established themselves as a dependable and economical choice for fire suppression across various uses, backed by a history of uninterrupted service. With technological progress, the importance of CPVC pipes in enhancing fire safety within structures globally is anticipated to grow significantly.

Post Comment