Determination of Density and Specific Gravity of Polymers/Plastics: Compliance with ASTM D 792 and IS 13360

Specific Gravity-Specific gravity is defined as the ratio of the weight of the given volume of a material

to that of an equal volume of water at a stated temperature. The temperature selected for determining the specific gravity of plastic is 23C. Density: The density of plastic material is defined as the weight per unit volume and is expressed in g/cm 3 or lb/ft 3 .

Significance: Method A is used for a specimen in forms such as sheet, rods, tubes, or molded

articles. Method B is developed mainly for material in the form of molding powder, flavors or pallets.

Test Methods: ASTM D 792, ISO 1183, IS-13360, BS-2782-PT-5-1970

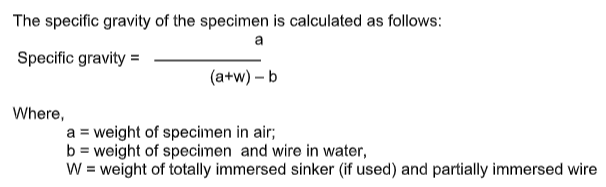

Method (A): This method requires the use of a precision analytical balance equipped with a stationary support for an immersion vessel above or below the balance pan. Corrosion0 resistant wires for suspending the specimen and a sinker for lighter specimens with a specific gravity of less than 1.00 are employed. A beaker is used as an immersion vessel. The test specimen of any convenient size is

weighed in air. Next, the specimen is suspended from a five wire attached to the balance and immersed completely in distilled water. The weight of the specimen in water is determined.

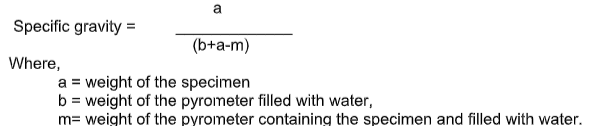

Method (B): This method, suitable for pallets, flakes, or powder, requires the use of an analytical balance, a pyrometer a vacuum pump, and a vacuum designator. The test is started by first weighing the empty pyrometer. The pyrometer is filled with water and placed in a water bath is attained. The weight of the pyrometer filled with water is determined. The pyrometer is filled with water and placed in a vacuum

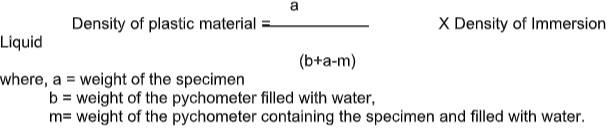

desiccators. The vacuum is applied until all the air has been removed from between the particles of the specimen. Lastly, the weight of the pyrometer filled with water and the specimen is recorded. The specific gravity is calculated as follows:

Procedure:-

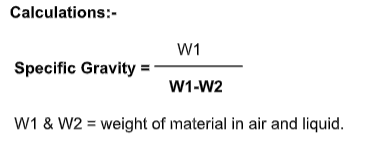

1) Clean and well dry the empty beaker and fill the n-butyl liquid as a fixed level.

2) Weight the plastic material, which is placed on upper part of beaker with in the report of air.

3) After that plastic materials put in to inner part of immersion liquid and weight it.

4) Observe the weight of plastics material in air and water.

Factors Influencing:

1. Temperature of testing: The specific gravity is inversely proportional to the temperature.

2. Humidity of Environment: The specific gravity is inversely proportional to the humidity level in moisture sensitive material.

3. Effect of Reinforcing Filler: The specific Gravity is directly proportional to the loading of reinforcing Filler.

4. Foaming of Plastics: The Specific Gravity is inversely proportional to the % of foaming of plastics

5. Cross-linking of Plastics: The specific gravity is directly proportional to the % of cross-linking of Plastics

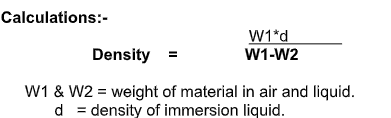

DENSITY

Density: The density of plastic material is defined as the weight per unit volume and is expressed in g/cm 3 or lb/ft 3 .

Significance:

1.Method A is used for a specimen in forms such as sheet, rods, tubes, or molded articles.

2. Method B is developed mainly for material in the form of molding powder, flavors or pallets.

3. Method C is used for a plastic material and product. Method C is used for Thermo set material and product.

Test Methods: IS-13360, BS-2782-PT-5-1970

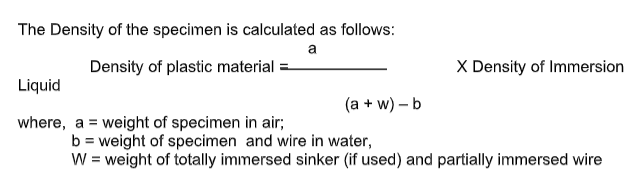

Method (A): This method requires the use of a precision analytical balance equipped with a stationary support for an immersion vessel above or below the balance pan. Corrosion resistant wires for suspending the specimen and a sinker for lighter specimens with a specific gravity of less than 1.00 are employed. A beaker is used as an immersion vessel. The test specimen of any convenient size is weighed

in air. Next, the specimen is suspended from a five wire attached to the balance and immersed completely in distilled water. The weight of the specimen in water is determined.

Method (B): This method, suitable for pallets, flakes, or powder, requires the use of an analytical balance, a pychometer a vacuum pump, and a vacuum designator. The test is started by first weighing the empty pychometer. The pychometer is filled with water and placed in a water bath is attained. The weight of the pychometer filled with water is determined. The pychometer is filled with water and placed in a vacuum

desiccators. The vacuum is applied until all the air has been removed from between the particles of the specimen. Lastly, the weight of the pychometer filled with water and the specimen is recorded. The Density is calculated as follows:

Method(C): The test method developed to determine the density of plastics very accurately is based on observing the level to which a test specimen sinks in a liquid column exhibiting a density gradient in comparison with standard specimens of known density, a number of calibrated glass floats of precisely known density are introduced into the density gradient and allowed to sink in the column to a point

where the glass floats density matches that of the solution. A series of such floats of differing densities within the range of the column serves as a means of calibrating the column. The float position versus float density is plotted on a chart large enough to be read accurately to 1mm to obtain a calibration line. When a specimen of unknown density is introduced into the column, the measurement of its position upon reaching equilibrium, when referred to the calibration line gives an accurate measurement of its density.

(a) Bulk (apparent) density test: Apparent density is a measure of the fluffiness of a material. Bulk density is defined as the weight per unit volume of a material, including voids inherent in the material as tested. Bulk density is commonly used for materials such as molding powders. The test method to determine bulk density.

Test Procedure:

1) Clean and well dry the empty beaker and fill the n-butyl liquid as a fixed level.

2) Weight the plastic material, which is placed on upper part of beaker with in the report of air.

3) After that plastic materials put in to inner part of immersion liquid and weight it.

4) Observe the weight of plastics material in air and water.

Factor Influencing:-

1. Temperature of testing: The density is inversely proportional to the temperature.

2. Humidity of Environment: The density is inversely proportional to the humidity level in moisture sensitive material.

3. Effect of Reinforcing Filler: The density is directly proportional to the loading of reinforcing filler.

4. Foaming of Plastics: The density is inversely proportional to the % of foaming of plastics

5. Cross-linking of Plastics: The density is directly proportional to the % of cross- linking of plastics

Post Comment