HDPE PIPE Testing as per IS 4984

Pipes made from HDPE are produced from high-quality raw materials, employing advanced manufacturing technologies. HDPE pipes are engineered to meet the needs of applications such as water supply, irrigation, bore-wells, drainage, infrastructure projects, and various industries. These pipes come with numerous exceptional characteristics that guarantee lasting system efficiency while reducing maintenance expenses. Here we study about various testing involve in IS 4984 specification

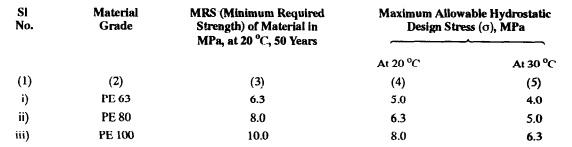

Classification of HDPE Pipe Material as per IS 4984

Major Testing covers in IS 4984 for HDPE PIPE Testing

1.Visual Appearance-The internal and external surfaces of the pipes shall be smooth, clean and free from grooving and other defects.

2. Dimensions (mm) -Measured by Pie Tape and Vernier caliper

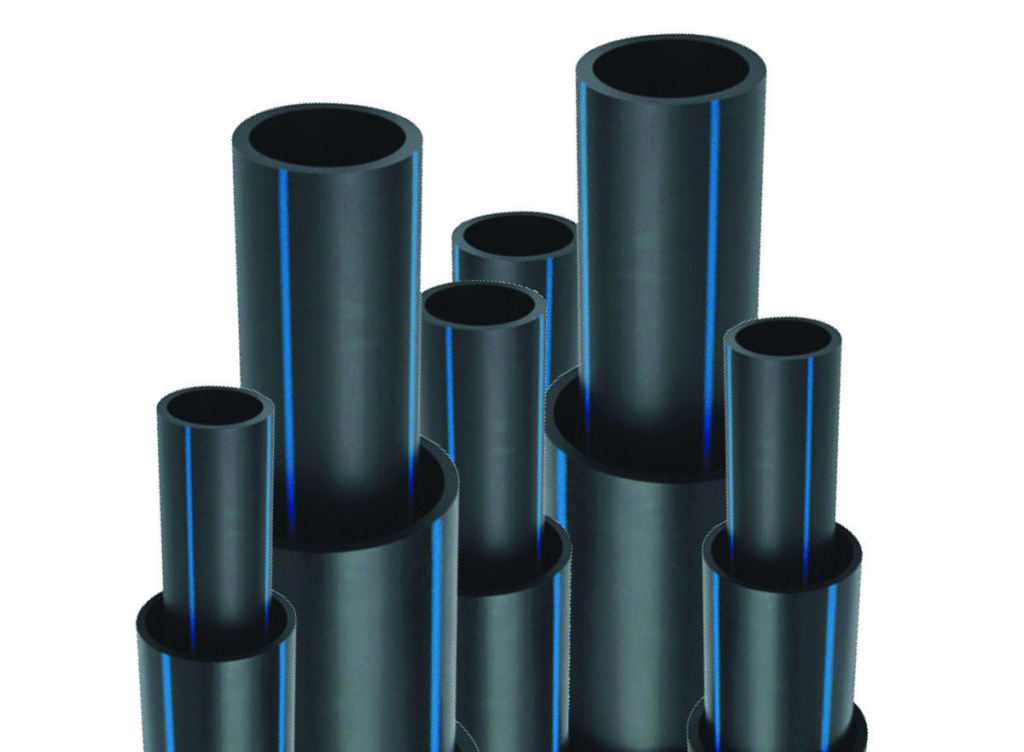

3. Colour: The colour of the pipe shall be black with blue identification stripes

4.. Carbon Black Content : 2.5± 0.5%

5.Carbon black dispersion :Shall be satisfactory

6. Density at 27°C : 940 – 960 kg/m³

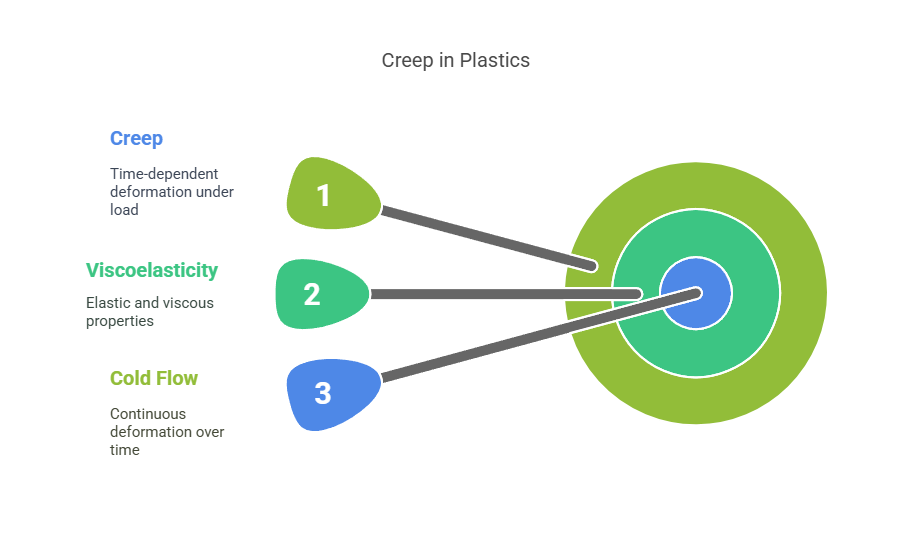

7. Hydraulic Characteristics: At various induced stress and 80°C for 48 hrs. Shall not show signs of localized swelling, leakage or weeping and shall not burst during the prescribed test duration.

8. “Melt flow rate, g/10 min : Maximum +-30 percent MFR value of the base resin

(at 190°C, 5 kg)”

9.Tensile Strength at Yield : 15 MPa Minimum

10. Elongation at Break : 350% Minimum

11. Oxidation Induction Time (OIT) : 20 minute Minimum

12. Overall Migration Test: 10 mg/dm² Maximum

Matreial : The substance selected for pipe production must not pose a toxic risk, should UOL provide assistance Microbial growth should not lead to unpleasant outcomes. flavour or scent, muddiness or tinting of, water. Manufacturers of pipes are required to acquire a certificate for this.

impact from the producers of basic materials. The defined base density must fall within the range of 940.5

kg/m3 aud 946.4 kg/m3 (both inclusive) when measured at 27C as per the method outlined in Annex A of IS 7328: 1992. The density must not vary from the nominal value by more than 3 kg/m3.

For more details about various test in IS 4984 comment below i will post details of HDPE PIPE Testing

Post Comment