How to measure Creep using ASTM D 2990

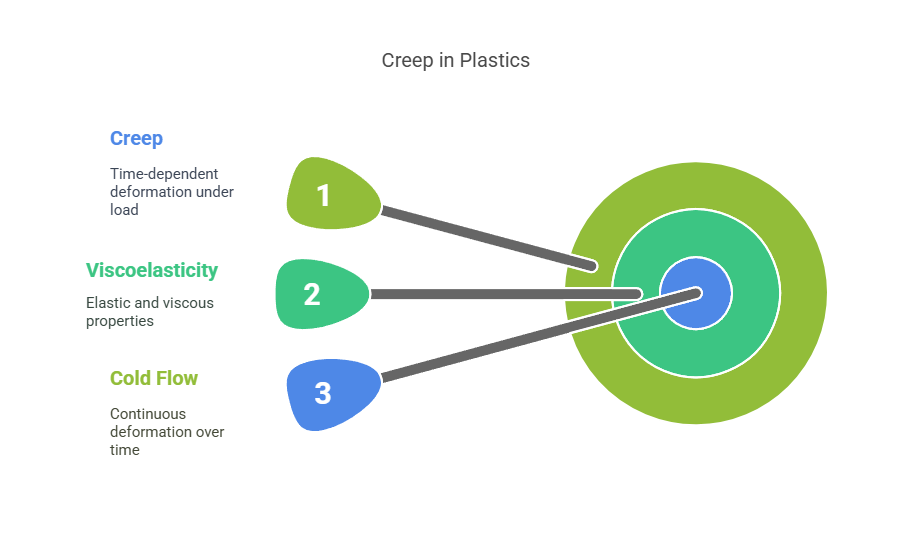

Creep: When a plastic material is subjected to a constant load, it deforms quickly to a strain roughly predicted by its stress-strain modulus, and then continues to deform slowly with time indefinitely or until rupture or yielding causes failure. This phenomenon under load with time is called creep.

Because of viscoelastic nature, a plastic subjected to a load for a period of time tends to deform more than it would from the same load released immediately after application and the degree of this deformation is dependent on the load duration. Creep is the permanent deformation resulting from prolonged application of stress below the elastic limit. Creep at room temperature is sometimes called cold flow.

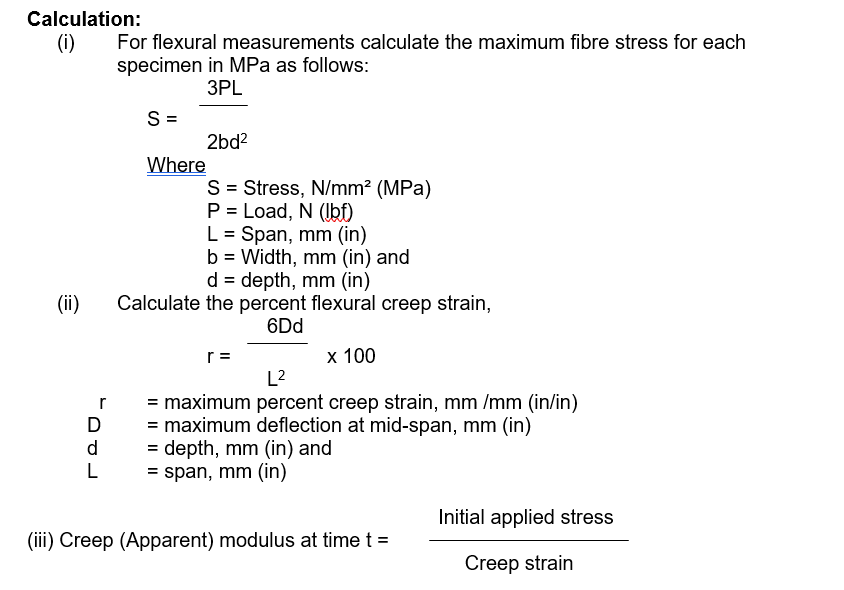

Creep Modulus (Apparent modulus): It is defined as the ratio of initial stress to creep strain.

Creep rupture strength: Stress required causing fracture in a creep test within a specified time.

Unit: Flexural Creep = lb/inch2

Test Methods: ASTM D 2990, JIS-7115

Specimen Dimension:

- The test specimen for tensile creep measurement is either type1 or type 2 as specified in test method D 638

- Specimen for unconfined compressive creep test is suitably prepared in the manner described in test method D 695, except that the length is increased so that the slenderness ratio lies between 11 and 15.

- Test specimen for flexible creep is a rectangular bar conforming to the requirements of section 5 at test method D-790.

- Test specimen is made by injection or compression moulding or machining from sheets or other fabricated form.

- Specimen prepared from sheets is cut in the same direction.

Tensile Creep:

- Mount a properly conditioned and measured specimen in the grips, tensile creep fixture.

- Attach the deformation-measuring device to the specimen.

- Apply the constant load to a tensile test specimen and smoothly to the specimen and measuring its extension as a function of time.

- The extension measurement is carried out by taking two gauge marks on the tensile specimen and measure the distance between the marks at specified interval time.

- Measure temperature, relative humidity and other environmental variables and deformation of control specimen with the some schedule as that for deformation of the test specimen.

Flexural Creep

- Flexural creep measurements are also made by applying a constant load to the standard flexural test specimen and measuring its deflection as a function of time.

- The deflection of the specimen at mid-span is measured using a dial indicator gauge.

- The electrical resistance gauges may also be used in place of a dial indicator.

- The deflections of the specimen are measured at a predetermined time interval.

Factors Influencing:

- Temperature of testing: The creep resistance is inversely proportional to the Temperature.

- Humidity of Environment: The creep Resistance is inversely proportional to the Humidity level in moisture sensitive material

- Effect of Reinforcing Filler: Creep resistance is directly proportional to the loading of Reinforcing Filler.

- Effect of Plasticizer: Creep resistance is inversely proportional to plasticizer.

- Aromatic Content & Cross-linking of Polymer: Creep resistance is directly proportional to the Aromatic Content & Cross-linking of Polymer.

Post Comment