Injection Moulding Part-2: A Guide to the Different Types of Injection Moulding Processes

Types of Injection Moulding

- Reaction injection moulding

- Liquid injection moulding

- Gas assist injection moulding

- Co-injection moulding

- Shot Injection moulding

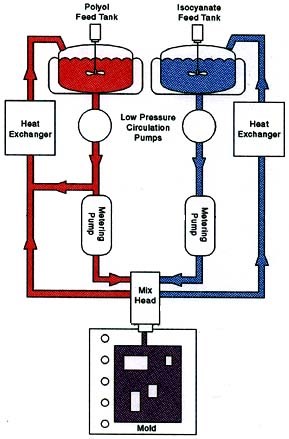

REACTION INJECTION MOULDING (RIM)

- RIM is a fabrication technique involving the extremely rapid mixing of two chemically reactive liquid streams, injected into a mould that results in the simultaneous polymerization, cross-linking and formation of the product.

- This process typically takes less than a minute to complete including time for mixing, curing and demoulding.

- This technique is a form of liquid injection moulding (LIM).

When short fibbers (1.6 mm), carbon or mineral fillers are incorporated into one of the liquids to increase modulus and reduce coefficient of expansion, the process is referred to as reinforced reaction injection moulding (RRIM).

Advantage

Strong, flexible, lightweight parts which can easily be painted.

Disadvantages

Slow cycles, expensive raw materials.

Applications

Automotive spoilers, interior trim panels for automobiles and trucks.

Liquid injection moulding (LIM)

- Process that involves an integrated system for proportioning, mixing and dispensing dual-component liquid resin formulations and directly injecting the resultant mix into a mould which is clamped under pressure.

- During LIM, pumping systems deliver a two-part liquid silicone (catalyst and crosslinker) directly into a mixer for homogenization.

- Using a relatively low pressure, the mix is then injected directly into heated mould cavities in 3 to 10 seconds.

Moulding and vulcanization (curing) occur inside the mould cavities within 10 to 90 seconds due to the high mould temperature

LIM process offers many benefits, including:

- Cleanliness with minimized contamination risk

- No material preparation labour

- Lower injection pressure

- Faster cycle rates

- Consistent part quality

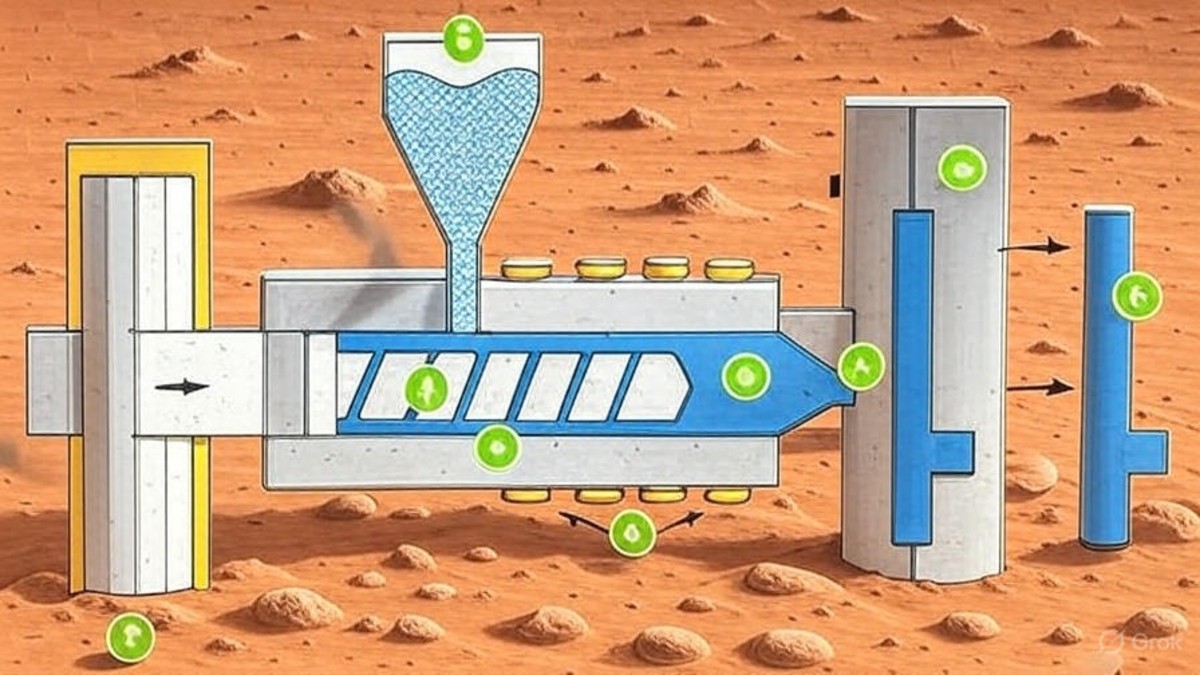

GAS ASSIST INJECTION MOULDING

- Gas-assist injection moulding is a process that utilizes an inert gas (normally nitrogen) to create one or more hollow channels within an injection-moulded plastic part.

- At the end of the filling stage, the gas (N2) is injected into the still liquid core of the moulding. From there, the gas follows the path of the least resistance and replaces the thick molten sections with gas-filled channels.

- Gas pressure packs the plastic against the mould cavity surface, compensating for volumetric shrinkage until the material solidifies.

- Finally, the gas is vented to atmosphere or recycled.

Variants of the Process

The main two applications of Gas- assisted moulding are to either inject the gas into the component cavity (internal gas injection) or to use the gas on the outside surface but still within the mould cavity, to consolidate the component (external gas injection).

Benefits of Internal Gas Injection Moulding:

- Substantial cost reductions resulting from:

- Reduction in moulded plastic weights and therefore cost of material.

- Reduction in moulding time cycles and therefore cost of production.

- Reduced in-mould pressures and therefore less wear on moulds.

- The use of the gas as a means of transmitting pressure uniformly throughout the moulding.

- Elimination of sink marks.

- Avoid plastic packing from the moulding machine.

- Reduced in-mould pressures up to 70% and therefore reduced press lock forces enabling larger mouldings on smaller machines.

- Reduced power consumption.

- Improves dimensional stability with no distortion.

Benefits of External Gas Injection Moulding:

- Eliminate sink marks.

- Virtually eliminates moulded-in stress and therefore distortion.

- Improves dimensional stability.

- Applies pressure more efficiently, and therefore less pressure is required:

– reducing lock forces or machine size

– reducing wear on moulds

– reducing power consumption - More design freedom:

– thicker ribs with reduced wall thicknesses

– multi-rib components

– flat PP and PE products

Raw Materials

PP, ABS, HIPS, PC, PPC and Nylon (including glass filled grades).

Advantages

- Material savings (weight, cost) for thick-walled parts up to 40%

- Reduced cycle times by 50% or more when compared to standard injection moulding of thick-walled parts

- Smooth surface in comparison with structural foam.

- External gas injection provides an enhanced surface definition of the component.

- Lower clamp forces

- Improved holding pressure effect

- High flexural stiffness and tensional rigidity

- Low internal stress level and low warpage for thick and thin wall combinations (uniform shrinkage and pressure)

- Reduction of sink marks

- Design freedom

- Fewer weld lines due to fewer injection points

- Longer flow lengths or lower number of injection points required for large thin-walled moulded parts because gas channels act as flow leaders

Disadvantages

- Special care must be taken in designing parts.

- High cost of tooling and mould flow analysis.

Applications

- Flat panels for office equipment.

- Computer enclosures.

- Furniture, i.e. tabletops.

- Automotive panels.

- Domestic appliances – e.g. fridges.

CO-INJECTION MOULDING

- This process creates a skin and core material arrangement in a moulded part.

- The skin material is injected first into the mould cavity followed by a core material.

- As the skin material flows into the cavity, the material next to the cavity walls freezes and material flows down a center channel.

- When the core material enters it displaces the skin material in the center of the channel by pushing the skin ahead.

- As it flows ahead it continues to freeze on the walls producing the skin layer

Machine Based Co-Injection

- Co-Injection process requires two injection/processing units.

- Injection/processing units inject material through a manifold located at the end of the injection barrels.

- The manifold ports the two melt streams into a centrally located nozzle.

- The machine controls the injection units to achieve a skin-core-skin flow sequence through the manifold into the mould.

- At last skin flow is needs to clear the short nozzle section of core material and to seal the gate area with skin. This arrangement can be used on any single or multiple cavities, conventional cold runner mould.

Mould Based Co-Injection

- This system, sometimes identified as “Mould Based Co-Injection”, still utilizes two injection units

- The two melt streams are directed into the mod via separate channels.

- These two channels remain separate until they reach the gate area of the part.

- At this point they flow through a nozzle arrangement similar to the normal co-injection manifold.

Advantages

- Lower cost parts

- Higher strength core

- Sound absorption core

- Reduced cooling time for lower temperature core

- Improved aesthetic qualities

- Combined property characteristics

Applications:

- Foamed core for reduced weight and noise transmission

- Glass filled cores for improved physical properties

- Low cost core for cost savings.

- High gloss skin material over structural core material for combination of aesthetic and structural properties.

- Post consumer recycled material in core.

SHOT INJECTION MOULDING

- This technology produces a part with two different raw materials or colours in a single operation.

- The machine has two injection units: one vertical and one horizontal.

- By using a rotating mould, the machine automatically produces a substrate of one resin or colour and overmoulds the part with the second resin or color.

Advantages

- Insert moulding and complex secondary operations are eliminated.

- Painting (which can rub off) is eliminated.

- Strong substrates can be moulded with soft-feel materials on the outside.

- Two-color applications can enhance appearance.

Disadvantages: High tooling cost.

Applications: Handles, triggers, knobs, dials and switches

Post Comment