Properties and Applications of Key Engineering Thermoplastics: Polyamides, Polyesters, Acetals, and PPO

Engineering Plastics are the family of Plastics that are capable of withstanding high loading for a period of time at elevated temperature and in adverse environments and behave in a predictable manner when subjected to design techniques. Engineering thermoplastics includes Polyamides, Polyesters, Acetals, and PPO.

They offer an additional capability of creating intricate and multifunctional part design, elimination of finishing operations such as self-threading etc.

Engineering Plastics exhibit a good balance of high tensile strength, Shear Strength, toughness to use as replacement of metals in many applications.

Advantages :

· Light Weight

· Rigidity

· High Impact

· High Temperature resistance

· Dimensional Stability

· Outstanding resistance to corrosion

chemicals, environmental stress

· Superior wear, fatigue, creep & other

load bearing properties

Five Major groups of Engineering Plastics

Crystalline materials

· Polyamides

· Polyesters

· Acetals

Amorphous materials

· Polycarbonates

· Modified Phenylene

POLYAMIDES

The Polyamides (nylons) were the first materials to be recognized as engineering thermoplastics. Polymides are polymers characterized by the amide group (CONH) as a part of the main polymer chain. The chemically the polyamides may be divided in to two types. I) those based on diamines and dibasic acids and ii) those based on amino acids or lactams. Aliphatic polyamides such as nylons 46, 66, 6, 610 and 11 are linear polymers and thus thermoplastic. The Nylon 6,6 is prepared from hexamethylene diamine and adipic acid. The polyamide 6 prepared from caprolactam.

The chemical structure of different types of polyamides are:

-[ HN (CH2)5 CO ]-n Polyamide 6

-[ HN (CH2)6 NH-CO (CH2)4 CO]-n Polyamide 6,6

-[HN(CH2)6NH-CO (CH2)8 CO]-n Polyamide6,10

-[ HN (CH2)10 CO ]-n Polyamide 11

-[ HN (CH2)11 CO ]-n Polyamide 12

PROPERTIES :

•Good combination of mechanical properties like Fatigue creep strength, stiffness, toughness and resilence

•Good abrasion resistance

•Self lubricating characteristics

•Suitable for prolonged, service temperature from – 400.C to 1200 .C

•Good electrical insulator, but the electrical properties are influenced by moisture content

•Resistance to fuels, oils, fats, most solvents and chemicals

•Low permeability to gas and vapours

•Non-toxic Easy processable by conventional processing techniques like injection, extrusion, blow and rotational moulding.

APPLICATIONS OF POLYAMIDES :

•Radiator fan

•Radiator grill

•Instrument housings

•Speedometer gears

•Fuel, oil filter housing

•Electrical junction box

THERMOPLASTIC POLYESTERS (PET/PBT)

Polyethylene terephthalate (PET)

Polyethylene terephthalate produced by the condensation reaction of ethylene glycol with either terephthalic acid (TPA) or dimethyl terephthalate (DMT). The production of PET resin is two step process. Dimethyl terephthalate is heated with ethylene glycol to form a mixture of dihydroxy ethyle terephthalate and higher oligomers. Step two is further heating to 270oC under vacuum, with the catalytic conversion of dihydroxyethyl terephthalate to PET.

POLYBUTYLENE TEREPHTHALATE (PBT)

Polybutylene terephthalate (PBT) is also called poly-tetramethylene terephthalate (PTMT) is a semi-crystalline polyester resin. PBT is produced by the catalytic polycondensation of 1, 4-butanediol and dimethyl terepathalate. Subsequent post-condensation raises transesterified product to the desired molecular weight.

PROPERTIES :

•Good electrical property

•Superior strength and stiffness

•Excellent dimensional stability

•Water repelance

•Outstanding chemical resistance

•Sterlisable by ethylene oxide and gamma rays

•Good abrasion resistance

•Low co-efficient of friction

•Excellent flame retardance

POLYACETAL

Acetalpolymers are properly called polyoxymethylene (POM). These resins are linear unbranched molecular chains derived from the monomer formaldehyde. The structure of homopolymer and copolymer are as follows:

—- CH2 – O – CH2 – O – CH2 – O – CH2 —— Polyacetal homopolymer

—- CH2 – O – CH2 – CH2 – O – CH2 —— Polyacetal Copolymer

APPLICATIONS OF POLYACETALS :

•Gears

•Bearing boxes and bushes

•Switch relays, terminal blocks and coil formers

•Blower fans, ventilation fans and pump parts

•Parts for office machines, house hold appliances and bathroom fittings

•Hinges

•Springs, snap fittings, screw

•Curtain rail runners

•Aerosol nozzles

•Nuclear engineering applications

•Plumbing fittings and components for pneumatic systems

•Automobile components such as radiator heater tapes, water filter bodies, fuel contact applications

•In irrigation system used in the areas of compression fittings, jets and sprayers

•Clock and watch parts

PROPERTIES :

•High impact strength even at sub zero temp.

•Remains flexible down to -150 Deg.C.

•Good creep resistance in dry conditions up to 115 Deg.C.

•Non-flammable, self extinguishing

•High heat deflection temperature

•Good dimensional stability

•Resistance to weak acids, hydrocarbons and oils

•Good electrical properties, stable over wide range of temperature, frequency and humidity

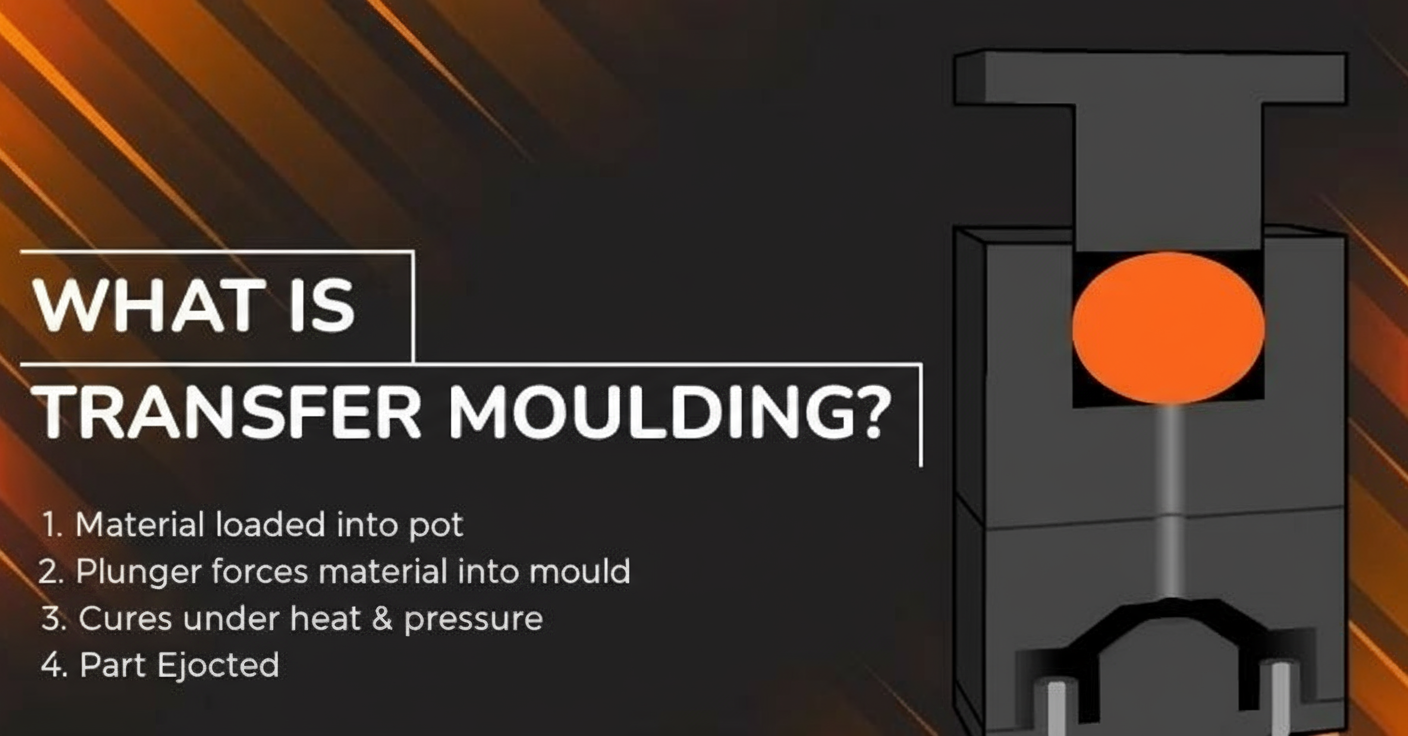

•Can be injection moulded, compression, transfer and blow moulded, extruded and easily machinable

POLYPHENYLENE OXIDE :

The chemical formulation is based on the oxidative coupling of substituted phenols and the elimination of a molecule of water. The full chemical name of PPO is poly [1, 4 – (2, 6-dimethyl phenyl) ether]

Polyphenylene Oxide (PPO) is used in blends with other Polymers. The neat Polymer is not suitable for injection moulding because of its high melt viscosity.

PROPERTIES:

•High Heat Resistance

•Excellent Impact Strength

•Exceptional dielectric and dissipation characteristics

•Flame Retardancy

•Exceptional low moisture absorption

Blends of Polyphenylene Oxide:

•PPO/PS blends, PPO/PA blends

Polyphenylene Oxide is completely miscible with Polystyrene in all proportions.

Applications : Automotive: Fenders, dash- boards, Head lamp systems, Instrument and Control Panels,

Mud-guards, Wheel Covers & Fuse Blocks etc.

Communications: Computer Housings, Television Cabinets, Telephone and Fiber Optic Connectors, Video display terminals, Control Panels, Printer Bases etc.

Post Comment