A Guide to Sprinkler Pipes in Irrigation Equipment: IS 14151 Part-1: 1999 (Reaffirmed 2021)

IS 14151 PART-1: 1999 (Reaffirmed 2021) is an Indian Standard titled “Irrigation Equipment – Sprinkler Pipes – Part 1: Polyethylene Pipes.

This standard is part of a series that provides specifications and requirements for irrigation equipment, specifically sprinkler pipes made of polyethylene.

Overview of IS 14151 Part-1: 1999 (Reaffirmed 2021)

Sprinkler pipes are an integral component of irrigation systems used for efficiently distributing water for agricultural, horticultural, and landscaping purposes.

As defined by IS 14151 PART-1: 1999, this standard lays down requirements and methods of tests for polyethylene pipes of outside diameter from 40 to 200 mm to be used for Sprinkler Irrigation Systems.

According to IS 14151 PART-1: 1999, sprinkler pipes are an integral component of irrigation systems used for efficiently distributing water for agricultural, horticultural, and landscaping purposes.

Understanding IS 14151 Part-1: 1999 (Reaffirmed 2021) for Irrigation Systems

This standard lays down requirements and method of tests for polyethylene pipes of outside diameter from 40 to 200 mm to be used for Sprinkler Irrigation Systems as mains, submains or laterals.

Key Insights on IS 14151 PART-1: 1999

Suitable Applications

- Versatile system ideal for a wide range of crops, including wheat, gram, pulses, vegetables, cotton, tea, coffee, hay, corn, and soybean.

- Perfect for commercial and residential gardens, as well as landscapes in industries, hotels, resorts, public institutions, and government premises.

- Well-suited for large green areas such as golf courses, race tracks, parks, and sports fields.

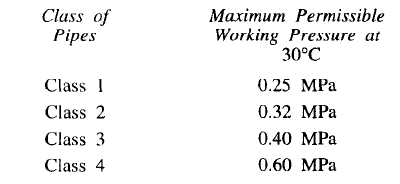

CLASSIFICATION OF PIPES :

Understanding IS 14151 PART-1: 1999 Standards

This specification consists of following tests and their requirements as per IS 14151 (Part 1) : 1999 (Reaffirmed 2021)

- Visual Appearance- The internal and external surface of the pipe shall be smooth, clean and free from grooving, pit marks and melt fractures.

- Dimensions, mm- Measured by using vernier caliper and pi tape

- Density at 27°C, kg/m³-940.0 – 958.4

- Carbon black content, %-2.5± 0.5

- Carbon black Dispersion-Shall be satisfactory

- Reversion, %-±3

- Melt flow rate, g/10 min (at 190°C, 5 kg)-0.2-1.1

- Tensile Strength , MPa-19 Minimum

- Hydraulic Characteristic At induced stress 3.8MPa and 80°C for 48 hrs.-Shall not show signs of localized swelling, leakage or weeping and shall not rupture during the prescribed test duration.

Material : The percentage of anti-oxidant in the base resin shall not be more than 0.5 percent by mass. The carbon black content in the material shall be within 2.5± 0.5 percent and the dispersion of carbon black shall be satisfactory

Reworked Material : Addition of not more than 10 percent of the manufacturer’s own rework material produced during the manufacture and works testing of pipes complying with this standard is permitted. No other rework material shall be used.

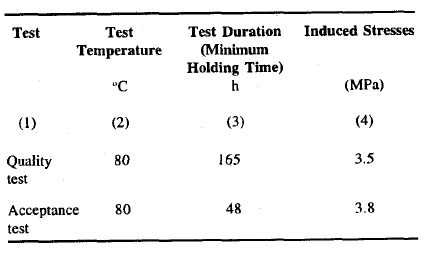

PERFORMANCE REQUIREMENTS :

When subjected to internal pressure creep rupture test in accordance with the pipes shall show no signs of localized swelling, leakage or weeping, and shall not rupture during the prescribed test duration. The temperature, duration of test and stresses for quality and acceptance test shall be as given in Table

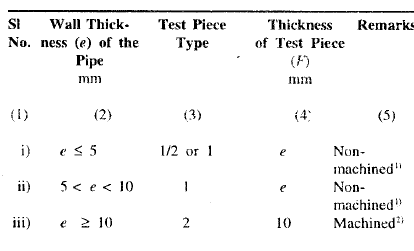

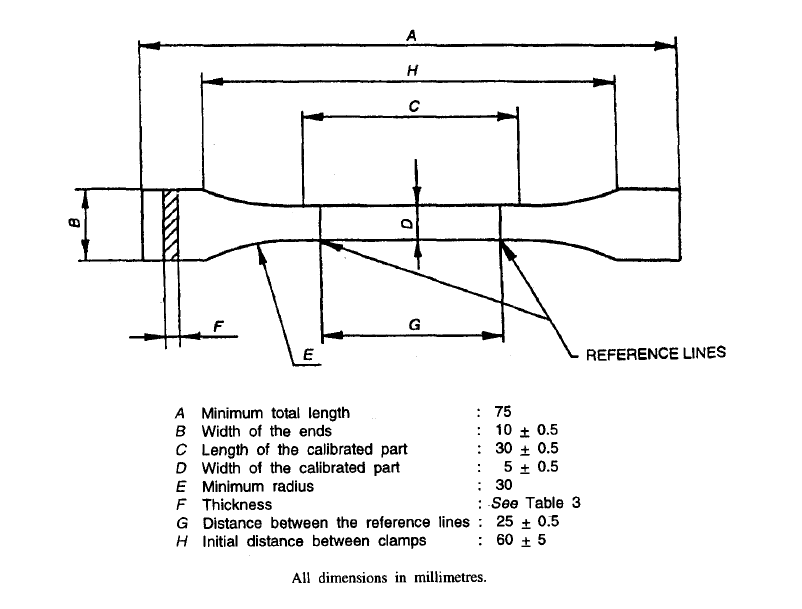

The tensile strength and elongation at break at 27°C for different thicknesses of the pipes shall

be as follows:

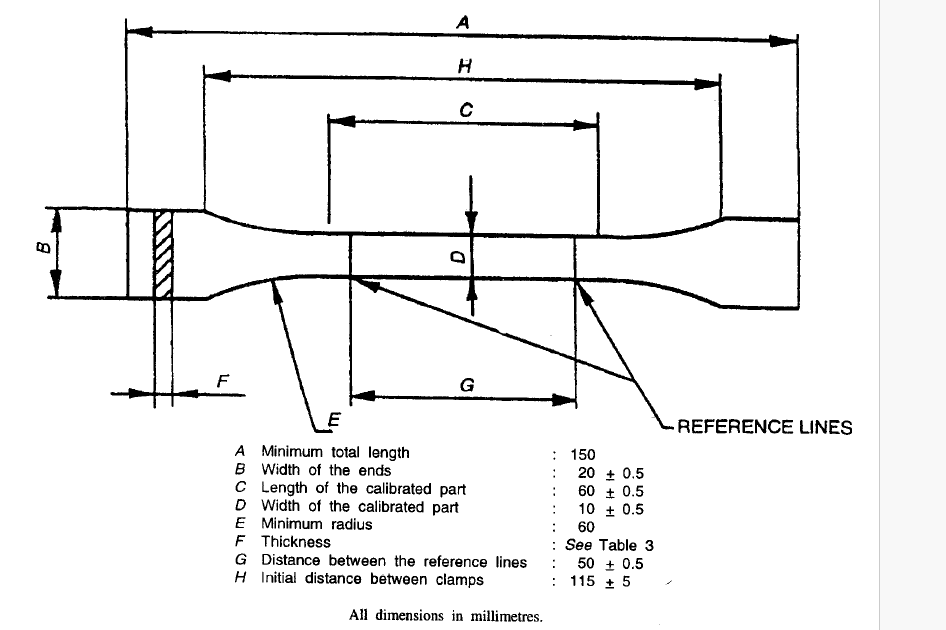

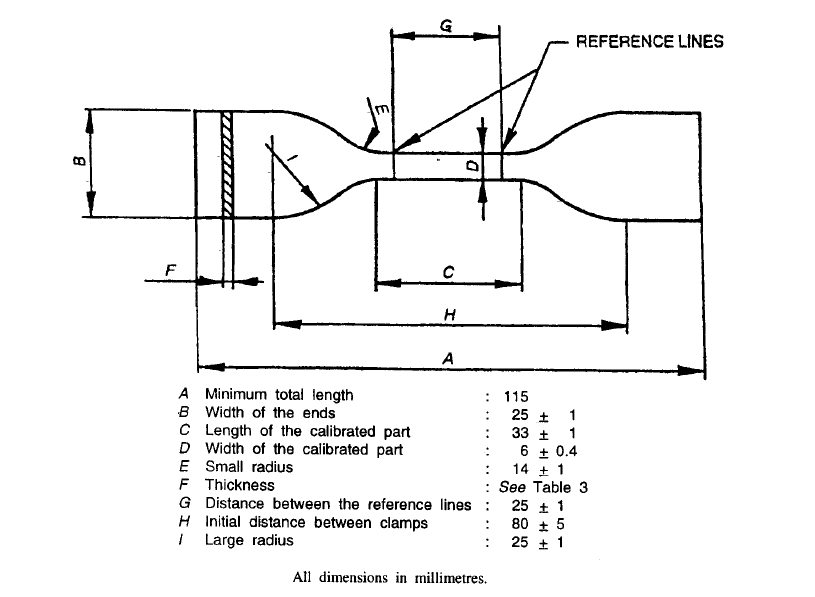

Selection of Test Piece based on wall thickness of pipe

Test Piece Type 1/2

Details of test piece dimensions given in below figure

Test Piece Type 1

Test Piece Type 2

SUPPLY OF PIPES

The pipe length excluding coupler attachment shall be either 3 m or 6 m ~ 0.01 m for shiftable sprinkler systems or as coils with a minimum inner diameter of 25 times the outer diameter of the pipe. The pipes may also be supplied in other lengths where so agreed to between the manufacturer and the purchaser. The ends shall be cut at right angles to the pipe axis.

Marking of Pipe

Class 1 – Orange

Class 2 – Red

Class 3 – Blue

Class 4 – Green

Key Features

- Achieves over 40% water savings compared to traditional flood irrigation methods.

- Ideal for undulating or uneven fields — no land leveling required.

- Lightweight, portable design ensures easy handling and movement.

- Significantly reduces transportation and labor costs.

- Quick, hassle-free installation using coupler-type joints for pipes and fittings.

- Superior corrosion resistance for enhanced durability and long service life.

- UV Stabilized – Offers strong protection against ultraviolet rays, ensuring reliable performance in outdoor and exposed applications.

- Highly Flexible & Impact-Resistant – Maintains integrity under high pressure and temperature while resisting cracks and breakage.

- Chemically Inert – Compatible with liquid fertilizers, pesticides, and a wide range of agricultural chemicals without degradation.

- Strong & Durable – Engineered for long-lasting performance, even in demanding field conditions.

- Cost-Effective Solution – Delivers high durability and efficiency while minimizing long-term maintenance costs.

Post Comment