Testing and Evaluation of Coefficient of Friction (COF) Following ASTM D 1894

Coefficient of friction– It is the ratio of the frictional force to the force, usually gravitational acting perpendicular to the two surfaces in contact. This coefficient is a measure of the relative difficulty with which the surface of one material will slide over an adjoining surface of itself or of another material.

Friction: The resisting force that arises when a surface of one substance slides or tends to slide over an adjoining surface of itself or of another substance.

There are two types of friction:

- The resistance opposing the force required to start to move one surface over another.

- The resistance opposing the force required to move one surface over another at a variable, fixed or predetermined speed.

Slip: It denotes the lubricity of two surfaces sliding in contact with each other.

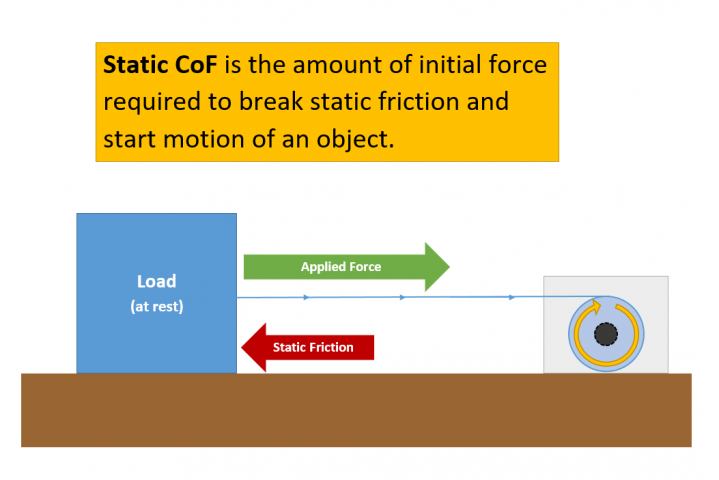

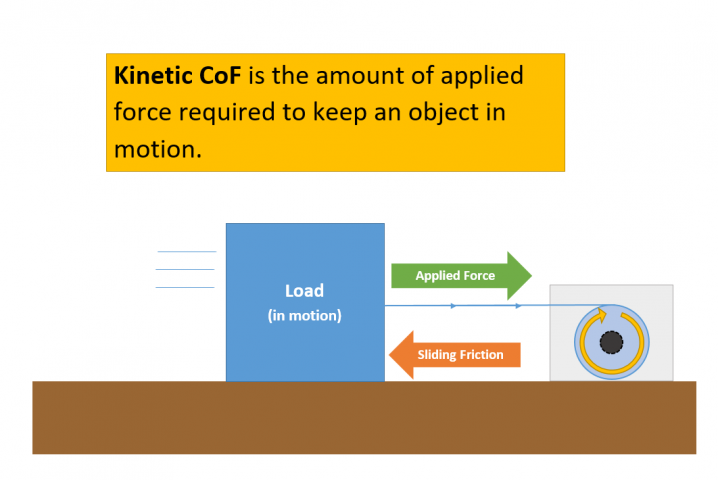

Coefficient of friction is broken down into two categories: Static and Kinetic. Here’s the difference:

Static coefficient of friction– The force needed to start moving is measured by the static coefficient of friction. The friction between bags when they are stacked or cartooned (plastic on plastic) is typically measured in the packaging business using the static coefficient of friction.

Kinetic coefficient of friction-The force needed to keep moving is measured by kinetic coefficient of friction. Kinetic coefficient of friction is typically used to rolls of plastic film that are processed on form fill seal packaging machines (plastic on metal) in the packaging business.

Significance :

- Measurements of frictional properties are made on a film or sheeting specimen when sliding over itself or another substance. The coefficients of friction are related to the slip properties of plastic films that are of wide interest in packaging applications.

- Slip properties are generated by additives in some plastic films for e.g. Polyethylene. These additives have varying degrees of compatibility with the film matrix. Some of them bloom, or exude to the surface, lubricating it and make it more slippery.

- Frictional and slip properties of plastic film and sheeting are based on measurement of surface phenomena where products have been made by the same process, their surface is dependent on the equipment or its running conditions.

- The measurement of the static coefficient of friction is highly dependent on the rate of loading and on the amount of blocking occurring between the loaded sled and the platform due to variation in time before motion is initiated.

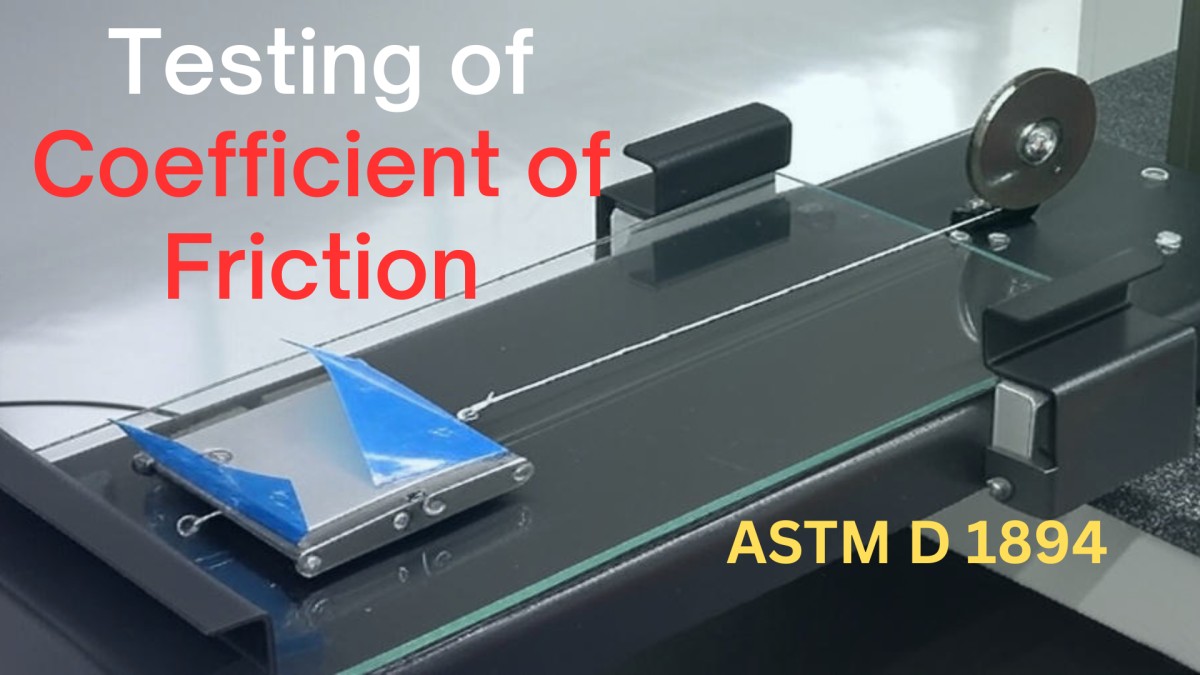

Test Methods: ASTM D 1894

Specimens Dimension:

- For plane specimen – 250 mm in the machine direction and 130 mm in the transverse direction

- For film specimen – 120 mm square

- For sheet specimen – 63.5 mm square

Conditioning: Test specimen is conditioned at 23 ± 2°C and 50 ± 5% relative humidity for not less than 48 hours.

Test Procedures:

- Tape the 250/130 mm film or sheet specimen to plane with the machine direction at the specimen in the 250mm direction.

- Smooth the film specimen to eliminate wrinkles. Care must be taken, not to alter the specimen surface through finger oils etc.

- Start the driving mechanism which is adjusted previously provides a speed at 150 ± 30mm/mm per min.

- Record the visual average reading during the run at app. 130mm where the surfaces are sliding uniformly over one month.

- This is equivalent to the kinetic force require to sustain motion between the surface normally lower than the static force required to initiate motion, after the sled has traveled over 130mm over stop the apparatus.

- Remove the film or sheeting from the sled and the horizontal plane.

- The apparatus is now ready for the next set of specimens.

- A new set of specimens is used for each run. Specimen surface(s) is tested more than once unless such tests constitute one of the variables to be studied.

Factors Influencing:

- Surface Conditions of the specimen: Surface finish has significant effect on the coefficient of friction results. A smooth moulded surface yield lower value than a machined surface.

- Test Speed: Higher the test speed is directly proportional to the values coefficient of friction.

- Sled Weight: Sled Weight inversely proportional to the values coefficient of friction

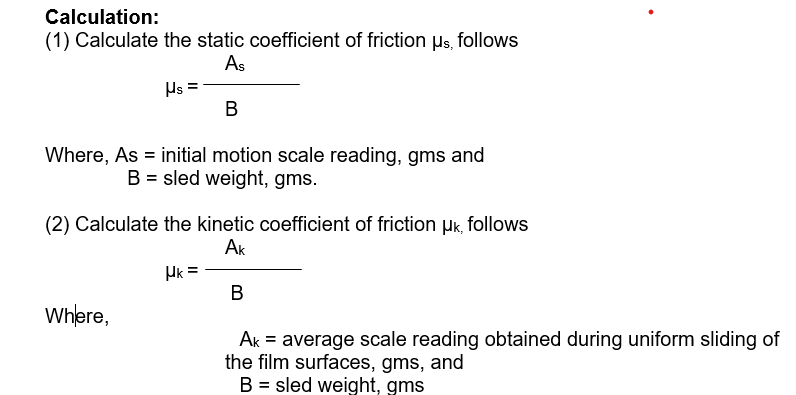

A friction testing device is typically used to measure the coefficient of friction. In essence, the force needed to move the plastic packing film is measured by dragging it across a stainless steel surface. The coefficient of friction is then determined by the person conducting the testing using a few mathematical computations.

The resultant figure will fall between 0 and 1.

Post Comment