Testing of uPVC Pipes for Soil, Waste, Ventilation, and Rainwater Systems – As per IS 13592

This standard (IS 13592) specifies the requirements for uPVC pipes and fittings used in:

- Soil and waste discharge systems (for both low and high-temperature waste)

- Ventilation systems

- Rainwater systems inside buildings

Features Of upvc pipe based on IS 13592 :

High quality and wide range –The system comprises pipes and a variety of fittings with different traps which makes the system comprehensive in all respects and hence customer does not need to depend on traditional systems.

Strong and long lasting – This system is highly robust, tough and durable with high tensile strength and high impact strength. In addition, it is immune to scale deposition, rusting, weathering and chemical attack so that it lasts for life.

Excellent chemical and corrosion resistance – Being non-metallic, this system has no possibility of corrosion and offers good resistance to a wide variety of chemicals.

UV resistance – This eliminates the harmful effects due to sunlight and weather and can therefore be used safely in outdoor installations.

Quick and convenient installation – Due to extremely light weight and with the special rubber jointing technique, installation becomes very easy. Quick and efficient removal of waste without leakage – Mirror surface

Basic Testing requirements of IS 13592 specification :

1. Visual appearance : The internal and external surfaces of the pipes shall be smooth, clean and free from grooving and other defects.

2. Colour : Shall be dark shade of grey

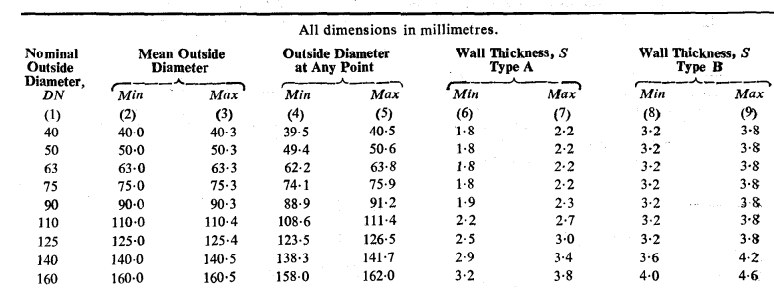

3. Dimensions, mm : Measured by using Vernier caliper and thickness gauge.

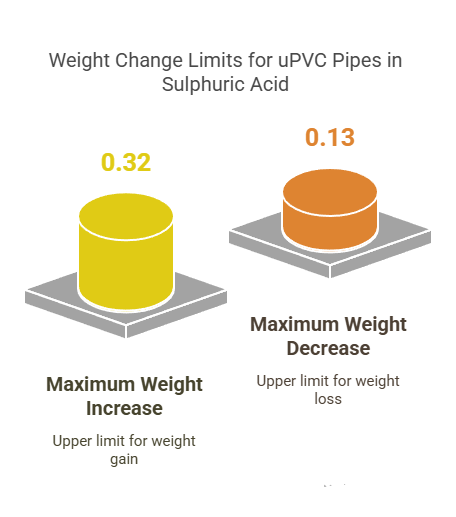

4. Resistance of sulphuric acid, weight increase or decrease, gm- Shall neither increase by more than 0.32 nor decrease by more than 0.13

5. Reversion, %- 5 Maximum

6. Vicat Softening Temperature,°C- 79 Minimum

7. Effect of sunlight (accelerated)- Shall not show differenc in colour or physical appearance

8. Resistance to external blow at 0°C (True impact rate), %-10 Maximum

9. Tensile strength at break, MPa –45 Minimum

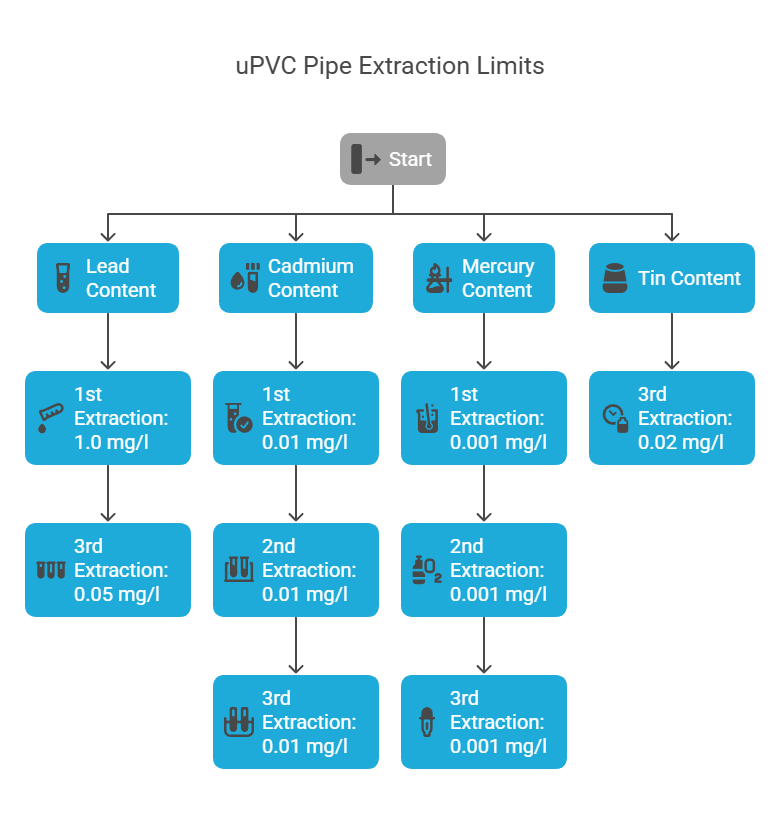

10. Effect on water :

i) Lead content, mg/l 1st extraction – 1.0 maximum 3rd extraction – 0.05 Maximum

ii) Cadmium content, mg/l

1st extraction 2nd extraction 3rd extraction – 0.01 Maximum

iii) Mercury content, mg/l

1st extraction 2nd extraction 3rd extraction – 0.001 Maximum

iv) Tin content, mg/l 3rd extraction – 0.02 Maximum

Dimensions of Pipe :

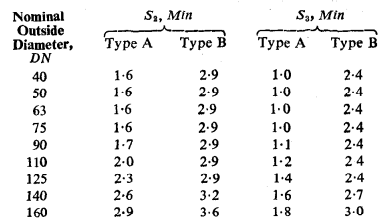

Minimum wall thickness of socket

Summery : Adhering to IS 13592 is crucial to guaranteeing the quality, safety, and performance of uPVC pipes used in soil, waste, ventilation, and rainwater systems. The standard’s requirements encompass a broad spectrum of properties, including visual appearance, dimensions, chemical resistance, and mechanical strength. This comprehensive coverage ensures that the pipes fulfill the required standards for their specific applications.

1 comment