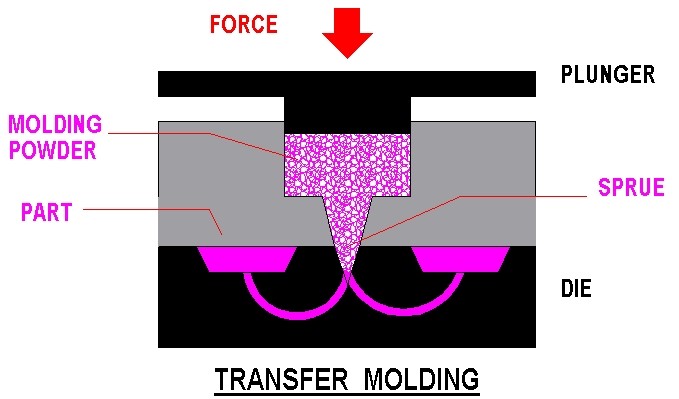

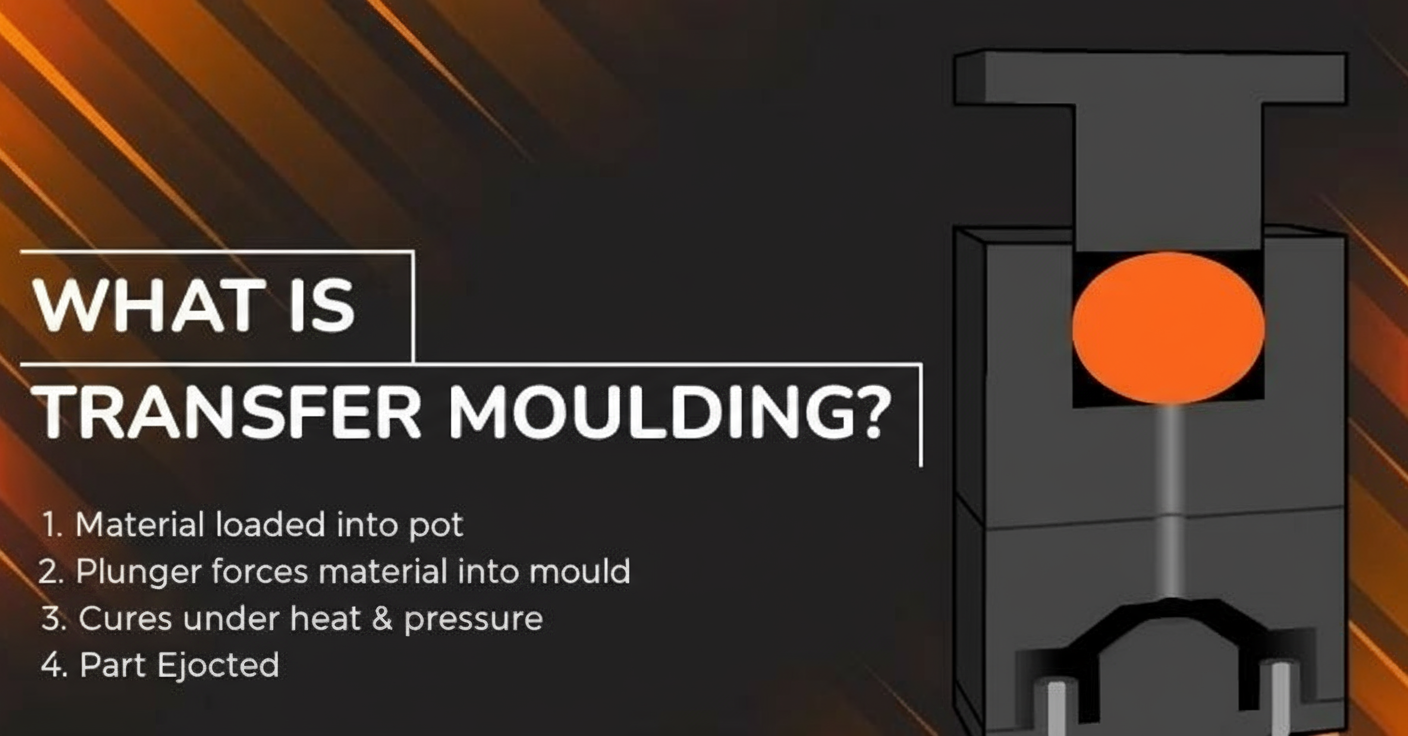

TRANSFER MOULDING

- Transfer moulding is a process like compression moulding where the amount of moulding material (usually a thermoset plastic) is measured and inserted before the moulding takes place.

- Used to make products such as electrical wall receptacles and circuit breakers

Process steps

| Step 1 – The moulding material is preheated and loaded into a portion of the mould called the “pot.” The plunger (on the top-most part of the mould) fits snugly into the “pot.” | |

| Step 2 – The mould is closed up and under hydraulic pressure the material is forced through the small hole (the “gate”) into the cavity. The mould is held closed while the rubber cures. | |

| Step 3 – The plunger is raised up and the “transfer pad” material may be removed and thrown away. | |

| Step 4 – Mould is opened and the part is removed. The flash and the gate may need to be trimmed. |

Advantages:

- Loading a preform into the pot takes less time than loading preforms into each mould cavity.

- Tool maintenance is generally low although gates and runners are susceptible to normal wear.

- Longer core pins can be used and can be supported on both ends, allowing smaller diameters.

- Because the mould is closed before the process begins, delicate inserts and sections can be moulded.

- Higher tensile and flexural strengths are easier to obtain with transfer moulding.

- Automatic de-gating of the mould’s tunnel gate provides cosmetic advantages.

Disadvantages:

- Moulded parts may contain knit lines in back pins and inserts.

- The cull and runner system of transfer moulding leaves waste material, but this scrap can be greatly reduced by injection moulding with live Sprues and Runnerless Injection Compression (RIC).

- Fiber degradation of orientation occurring in the gate and runner system reduces the moulded part’s impact strength.

- Compared to compression moulding, high moulding pressures are required for the transfer process, so fewer cavities can be put into a press of the same tonnage

Types of transfer moulding

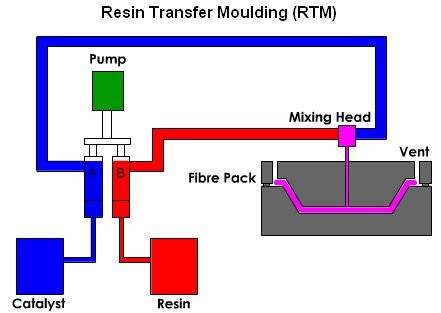

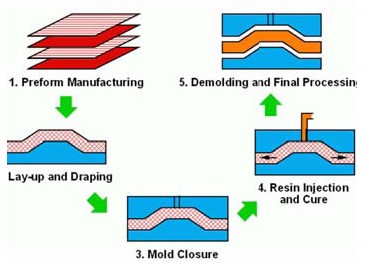

RESIN TRANSFER MOULDING (RTM).

- RTM is a low pressure moulding process, where a mixed resin and catalyst are injected into a closed mould containing a fiber pack or preform. When the resin has cured the mould can be opened and the finished component is removed.

- This is a variation of compression moulding and is particularly valuable when intricate shapes have to be moulded.

- It is also useful when metal inserts have to be incorporated (as in electrical component

- It is used frequently when the mould sections are very delicate, when the moulded parts has thick sections 3.2 mm or more, or when an insert is retained in the cavity for moulding in place.

- A wide range of resin systems can be used including polyester, vinylester, epoxy, phenolic and methyl methacylates etc, combined with pigments and fillers including aluminum trihydrates and calcium carbonates if required.

- The fibre pack can be either, glass, carbon, arimid, or a combination of these.

- The mould can be made from composites for low production cycles or with aluminum or steel for larger production.

Materials

- Reinforcement Materials:

Glass fiber, Carbon fiber, Kevlar fiber, surface veils (to improve surface finish)

- RESINS

Polyester resins – GP/Isophthalic/Vinyl ester/Bisphenolic, Epoxy resins, Phenolic resins and other thermoset resins

- Filters & Additives

- Low profile additives, internal release agents (used in case of hot moulds), Lubricants, viscosity modifiers or surface tension relievers/ UV Stabilizers, etc.

- Powder, calcium carbonate, Quartz powder, Alumina – Trihydrate, Titanium dioxide, Fine silica, etc. (added for requirements of cost reduction / insulation / part surface quality / to reduce shrinkage / flame retardancy, etc.)

- Pigment pastes – Polyester/Epoxy/Pigments of various colours, shades.

Comparison with the other moulding processes

a) Compared to Open Moulding, RTM offers:

- Lower styrene emission

- Reduced energy consumption

- Increased productivity

- Smooth finish on both sides of the product

- Elimination of gel coat, if required

- Elimination of “roll-out”

- Better cost control (material/labour)

- Less ventilation requirement.

b) Compared to Compression Moulding, RTM offers:

- Reduced mould cost and operating expenses

- Economical limited production runs

- Shorter lead times in mould construction

Advantages of RTM

- Wide Range of Production Quantity

The process can be tailored to individual application, rendering the technology suitable for a wide range of production quantities.

- Design Flexibility

RTM offers design flexibility of tailoring the materials closely to the applied loading system. One can mould shapes that are difficult, if not impossible, to form by conventional methods.

- Labour Savings

As the resin is pumped in the mould during the RTM process, the molder can reap the benefit of saving labour spent on impregnating the fibers.

- Lower Start-Up Cost

The initial cost is only a fraction of the high capital cost associated with matched mould operations for equipment and tooling.

- Dimensional Tolerances

RTM allows designers to have close tolerances in the product.

Surface Finish

High quality surface finish on both sides of the product is obtained in RTM process. The parts can be gel coated, pigmented or painted

Application

In the semiconductor industry, package encapsulation is usually done with transfer moulding due to the high accuracy of transfer moulding tooling and low cycle time of the process.

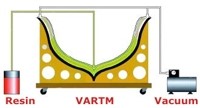

VACUUM ASSISTED RESIN TRANSFER MOULDING (VARTM)

- This method is also referred to as vacuum infusion process (VIP) moulding.

- VARTM is single sided moulding process where the dry preform (reinforcement or coring materials) is placed into the mould.

- VARTM parts are formed in an open cavity mould.

- The opposite side to the tool surface is primarily a vacuum bag surface comprises of transfer media, peel ply fabric, bleeder/breather media and sealant tape.

- A distribution medium (a mesh) is used and laid on top of the top release fabric to help maintain an even distribution of resin and facilitate the flow of resin through the thickness of the panel.

- The low viscosity resin typically enters the preform through resin distribution and vacuum distribution lines with the aid of vacuum.

Process

- Aluminium flat plate is cleaned with acetone and freekote is sprayed

- Non-porous teflon, porous teflon are laid up on the Al tool

- Dry fabric preforms are laid on the teflons and a distribution mesh is put over the fabric.

- Again porous teflon and non-porous teflon are laid up sequentially

- Spiral tubes were installed on two side of the distribution mesh. One for resin infusion and another for suction.

- Complete lay-up was covered with a thin heat-resistant vacuum bag and debulked for an hour

- Once debulking is completed, resin is infused.

- As resin flow appears to come out through the ejection line, resin flow is cut off.

- The vacuum is kept on while the resin is left for 24 hours to cure.

Materials

Resins: Any resin with low viscosity, e.g. epoxy, polyester, vinyl ester

Fibers: fabrics made from carbon, Kevlar, Quartz, glass and polyester fiber.

Advantage

- Cost-effective: VARTM uses vacuum power to pull the resin through the closed mould and to hold the two pieces together. This fact means that the “male” and “female” pieces of the mould can be much lighter, resulting in a significantly reduced price of fabrication.

- Vacuum assisted resin transfer moulding (VARTM) is ideal forthe manufacture of large-scale composite structures.

- The advantages of the VARTM process over the RTM process are scalability and affordability for the fabrication of large composite structures

Application

Post Comment