Compression Molding: Materials, Methods, and Applications

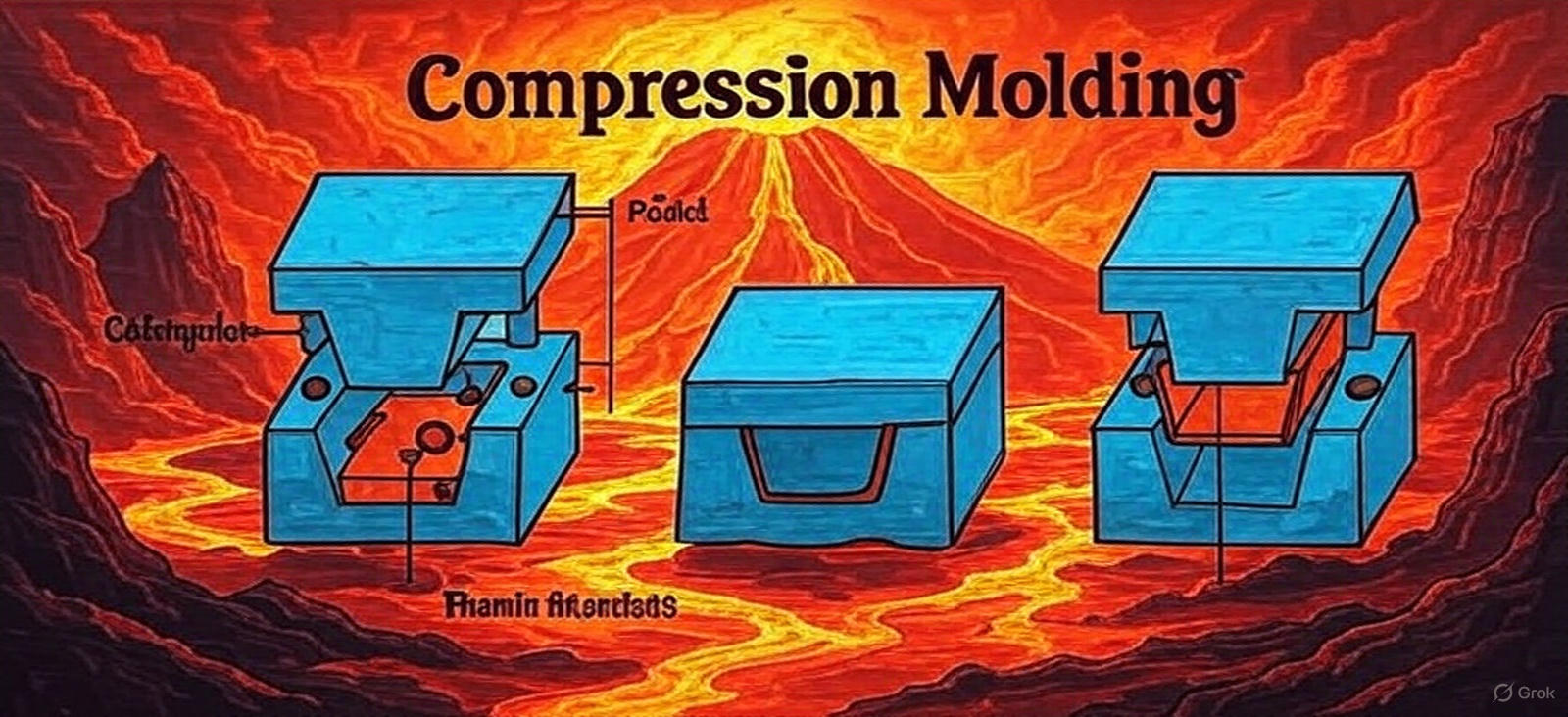

- Compression moulding is a process of moulding a material in a confined shape by applying pressure and heat.

- The mould is closed with a top force or plug.

- Pressure is applied to force the materials come in contact with all mould areas.

- Heat and pressure are maintained until the moulding material has cured.

- The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

- Compression moulding is a high-volume, high-pressure method suitable for moulding complex, high-strength fiber glass reinforcements.

- Advanced composite thermoplastics can also be compression moulded with unidirectional tapes, woven fabrics, randomly orientated fiber mat or chopped strand.

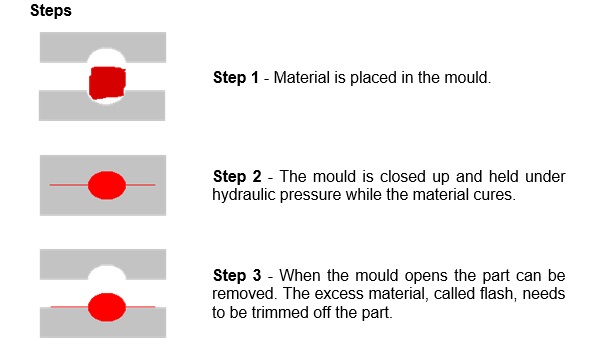

Operating Process

- Turn machine on and set to appropriate pressure and temperature.

- Have mould inserted into the machine.

- Heat up mould to appropriate temperature required.

- Check temperature with digital/analog thermometer

- When desired temperature is reached, extract mould from the machine.

- Open mould into two halves.

- Put appropriate amount of resin into one of the halves.

- Close the mould halves.

- Place back into the machine.

- Press the button that will cause the platen to clamp together

- Pressure is now being applied to the mould.

- Pressure is now being applied to the mould.

- The heat and pressure begins to liquefy the resin and fills the mould.

- When the appropriate amount of time has passed, the platens release pressure from the mould.

- Wearing gloves, remove the mould from machine.

- Separate the mould halves.

- Push the ejector pin to knock finished product out of mould.

- Repeat these steps to make additional moulds.

- Temperatures and time setting may vary with different resins or moulds.

- When done, shut the machine down appropriately and clean work area.

Parameters

Preheating:

- Preheating is useful to reduce moulding time and allows rapid heating of large pellets or masses of powder.

- It helps to remove moisture and other volatiles prior to moulding .

The quantity of resin put into the mould:

- If sufficient resin is not placed in the mould cavity, the part will not be formed completely.

- If too much material is applied into the mould, it may not melt completely or excess flash may be produced.

Pressure of the moulding process:

- The fluid plastic is held under pressure, often ranging upwards from 2000 psi, for a sufficient length of time for the material to undergo polymerization or cross linking, which renders it hard and rigid.”

- Different materials require different forces to mould them.

- High-viscosity materials require more pressure than materials with low-viscosities.

Down stroke or Upstroke of the machine:

- A down stroke machine consists of a compression press in which the platen moves downward to close the mould.

- An upstroke machine consists of a compression press where the platen moves upward to close the mould.

Mould Temperature:

- The mould is subjected to high levels of heat, approximately around 300ºF to 375ºF. Appropriate heating is crucial to allow for the resin to soften it to flow into the mould cavity.

- If the temperature is too low the plastic material my not melt completely and produce an unfinished part.

- If the temperature too high, it can cause the part to get burned or warped.

Breathing Time

- When the mould is closed, several changes takes place

- The temperature of the material has been raised almost that of the mould

- Chemical reaction starts

- Volatile gases have developed

- If volatile cannot escape through mould vents or between clearances of cavity moulding pressure drops to zero.

- After breathing, the mould is again pressurized for the duration of the cure.

- With slower reacting materials or thick sections, degassing can be accomplished more than once, but only in the early phase of the cycle.

- Usually visual inspection of surface or interior sections indicates the correctness of the degassing sequence.

- Condensation resins are more troublesome in formation of blisters or porosity.

- Any compound is likely to contain moisture and all materials and mould cavities contain air, which may make degassing necessary.

- Since breathing a mould included in the cure cycle, production time is not increased.

Moulding Cycle Time

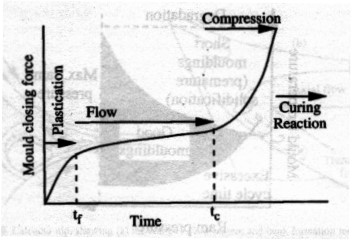

- Moulding cycle time can be represented as a function of the force required to close the mould at a constant rate.

- In the “plastication” stage (t<tf) the force increases rapidly as the polymer feed is compressed and heated.

- The second stage flow commences, once the yield stress of the elastomer is exceeded. tc is the point at which the mould fills and compression of the melt occurs.

- Ideally to aid mould filling the majority of chemical reaction should take place after tc.

Mould Closure Types

There are three basic types of moulds used when performing compression moulding.

- Flash Moulds are used for production of items when:

- Variation in wall thickness or eccentricity is permissible

- The radius is comparatively small or the corner is square on the outer edge of the open end of the moulding;

- The material is not full fabric and the displacement of the mould cavity is sufficiently large to contain the required moulding material in powder form or in some cases preforms.

- Positive Moulds

- Positive moulds are used occasionally when test pieces need to be made.

- Semi Positive Moulds

- Semi positive moulds are a combination of flash and positive moulds, and that the flash is separated from the material.

- Semi positive moulds are designed for three purposes: to provide a powder cavity for bulky material, to provide a powder cavity for bulky mouldings in any material and to provid

Key Advantages of Compression Molding Techniques

| Advantage | Description | Key Benefit |

|---|---|---|

| Minimal Waste | Near-net shape process with little scrap material. | Cost-saving on expensive materials (e.g., composites). |

| High Strength | Uniform fiber distribution and low void content. | Produces structurally superior, reliable parts. |

| Large Part Capability | Economical for very large, bulky components. | Enables manufacturing of parts other processes can’t. |

| Low Tooling Cost | Molds are simpler than injection molds. | Lower initial investment for production. |

| Low Residual Stress | Material is not sheared excessively during flow. | Parts have better dimensional stability and less warping. |

| Excellent Surface Finish | High-quality mold surface is replicated onto the part. | Reduces post-processing and polishing needs. |

Applications Highlighting These Advantages:

- Automotive: Tires, rubber gaskets, high-strength composite body panels (hoods, fenders), brake pads.

- Aerospace: Large composite panels, structural components.

- Consumer Goods: Appliance housings, plastic dinnerware (melamine), buttons, and electrical sockets.

- Industrial: Electrical insulators, circuit breakers, and large storage bins.

Post Comment